Machinery and equipment for the wheel industry

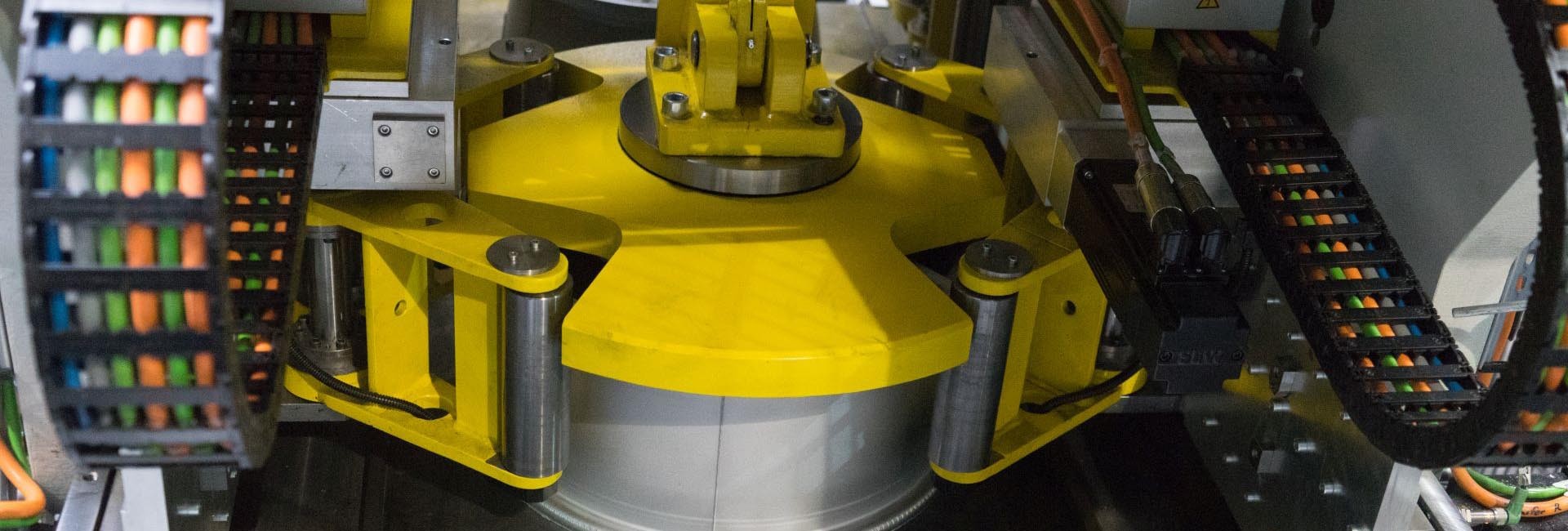

G+K builds machinery that meets demanding performance requirements and complies with the highest environmental standards. In the field of equipment for the wheel industry, we offer machinery that enables the automated processing of casting blanks for automotive wheels.

Our systems for the wheel industry focus on removing the riser casting as well as deburring the front horn and the four parting lines.

Our machinery analyzes the wheel, automatically recognizes its features, and then performs the corresponding processing steps.

A chaotic wheel feed is thus possible. G+K has the necessary know-how in the field of wheel manufacturing.

All our systems integrate smoothly into existing production lines and are designed as continuous systems.

What steps are required after casting an aluminum coating?

After casting an aluminum rim, several steps are required to prepare the rim for use. These steps include:

-

Demolding: The cast rim is removed from the mold. This can be done manually or with the help of machines.

-

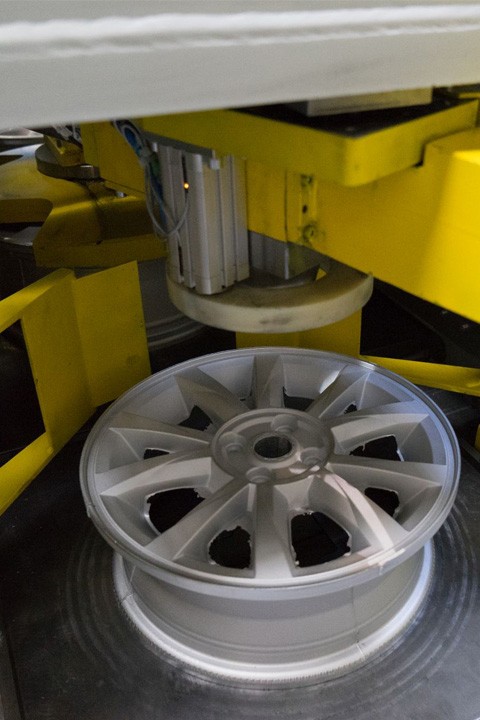

Deburring and edge removal: Protrusions and burrs that occur during the casting process are removed. This is often done through mechanical drilling, grinding, or milling. This is precisely where our machines come into play, controlling these processes.

-

Heat treatment: The rim undergoes a heat treatment to enhance material properties such as hardness and strength. Typical heat treatments include the T6 process, which involves solution heat treatment followed by artificial aging.

-

Mechanical Processing: The rim is precisely worked on in various areas to ensure accurate dimensions and tolerances. This includes turning, milling, and drilling holes for the fastening screws.

-

Surface treatment: The surface of the rim is treated to make it visually appealing and corrosion-resistant. Common procedures include grinding, polishing, blasting (e.g., sandblasting), and chemical treatment.

-

Coating: The rim is painted or coated to provide an attractive appearance and additional protection against corrosion. This includes powder coating or applying clear lacquer.

-

Quality Control: The rim undergoes a thorough inspection to ensure it meets quality standards. This includes both visual inspections and technical tests, such as X-ray inspections to detect internal defects and mechanical tests to determine strength and durability.

-

Balancing: The wheel is balanced to ensure that it runs smoothly at high speeds and does not cause vibrations.

-

Assembly of accessories: Any necessary accessories, such as valves or wheel covers, are installed.

-

Verpackung und Versand: Schließlich wird die fertige Felge verpackt und für den Versand vorbereitet.

These steps ensure that the aluminum wheel meets the requirements for safety, performance, and aesthetics before it is delivered to the customer.

Would you like to learn more about our machines for processing aluminum rims?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for your system

- Clarification of which rims and which process should be used to process them

- Discussions with design and production

- Access to confidential videos

- Coffee and snacks

Please feel free to contact me to arrange an appointment.