Customizable Hydraulic Tool Testing Press

What is a hydraulic tool testing press?

A hydraulic tool testing press is an industrial machine that uses hydraulic force to test and inspect tools. These presses are typically used in workshops, production environments, or laboratories to ensure that tools meet the intended specifications and function properly.

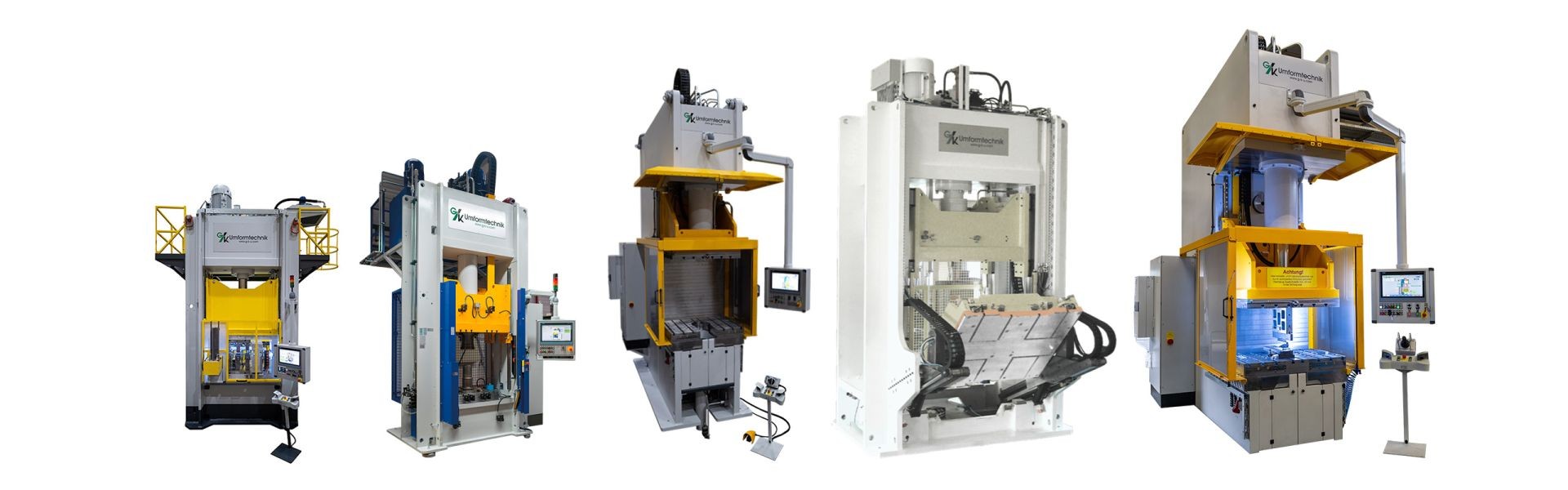

Tool testing press type HPV 100/S

The G + K hydraulic trial presses are fundamentally very stable production presses manufactured in a double-column design, featuring a control system that is optimally adapted to the specific requirements of toolmaking.

These machines are used to either observe or adjust tools through an extremely precise piston movement. The piston movement is controlled by a joystick. The movements are exceptionally well-controlled and can be handled with extreme sensitivity in both path and force. On the other hand, in the single stroke or continuous stroke function, the motion sequence of the production press or stamping machine is fully simulated. The time savings from extensive and realistic testing of the tools lead to an exceptionally short amortization period for the investment.

G+K presses are built with a solid welded steel frame and feature highly precise ram guidance through linear guides. The access to the tool table is generously open for easy tool changes.

Customizable parameters of our hydraulic tool test presses

Pressure force

This parameter indicates the maximum force (in tons) that the press can exert when testing tools or components. The pressing force is crucial for the press's ability to apply the required loads to tools.

Stroke length

The stroke length refers to the maximum vertical movement of the ram or the pressing head (in mm). It indicates how far the ram can be lowered and affects the testing depth or the stroke of the press.

Working speed

The speed (in mm/s) at which the ram is lowered and raised affects the efficiency and accuracy of the tool testing.

Work surface

The size of the working area (in mm x mm), where the tool to be tested is placed, affects the maximum size of the tools that can be tested.

Tool change system

Some hydraulic tool test presses are equipped with automated tool changing systems to facilitate the exchange of tools for different tests.

Energy consumption

The energy consumption of a hydraulic tool testing press can be a factor, especially when it comes to operating costs and environmental impact.

Control system

The control system can be manual, semi-automatic, or fully automatic, and it affects the operability and the degree of automation of the tool testing press.

Security features

Modern hydraulic tool testing presses are often equipped with various safety features, such as light barriers, emergency stop switches, and safety zones, to prevent accidents.

Would you like to learn more about our tool testing presses?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for the new tool test press

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding the tool test press.