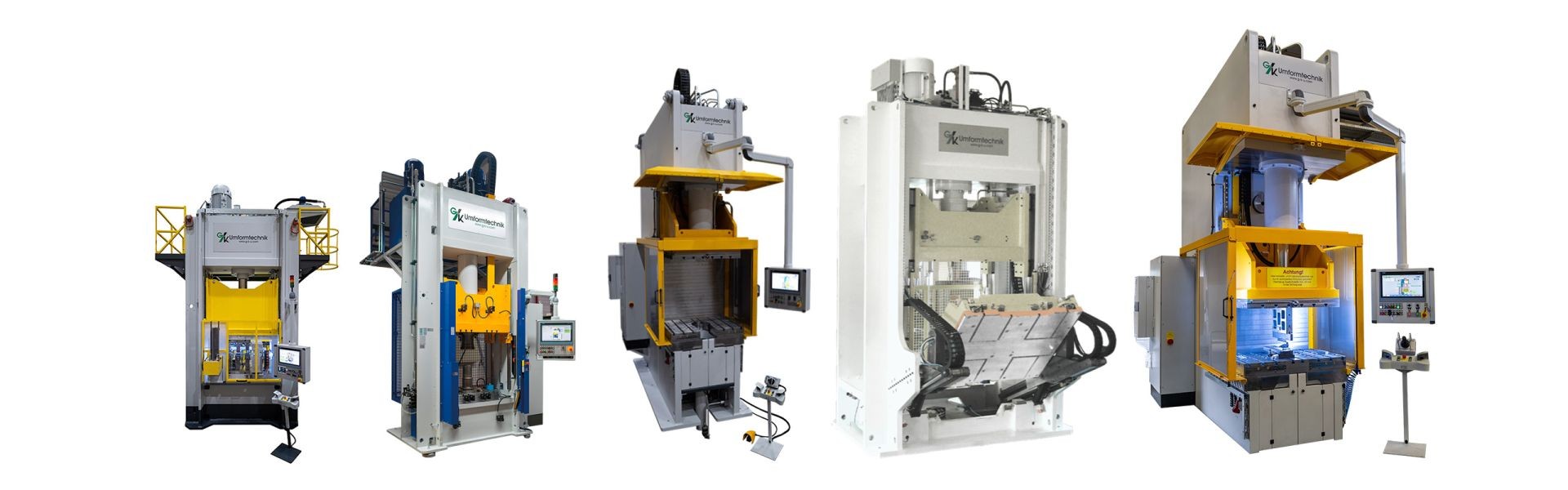

Customizable hydraulic forging press

What is a hydraulic forging press?

A hydraulic forging press is an industrial machine that uses hydraulic power to forge or shape materials. The forging process involves deforming metal by applying pressure and heat to achieve the desired shape. Hydraulic forging presses are specifically designed for these demanding forming processes and are often used in the forging industry.

Customizable parameters of our hydraulic forging presses

Pressure force

This parameter indicates the maximum force (in tons) that the press can exert when forging materials. The pressing force is crucial for the press's ability to forge the material.

Stroke length

The stroke length refers to the maximum vertical movement of the forging tool or press head (in mm). It indicates how deeply the material can be drawn into the mold.

Work surface

The size of the work area (in mm x mm), where the material to be forged is placed, affects the maximum size of the forged pieces produced.

Tool change system

Some hydraulic forging presses feature automated tool change systems to facilitate the exchange of forging tools.

Energy consumption

The energy consumption of a hydraulic forging press can be a factor, especially when it comes to operating costs and environmental impact.

Control system

The control system can be manual, semi-automatic, or fully automatic, and it affects the operability and level of automation of the stamping press.

Security features

Modern hydraulic forging presses are often equipped with various safety features, such as light curtains, emergency stop switches, and safety zones, to prevent accidents.

Material thickness

The maximum material thickness that the press can forge is an important parameter and depends on the design of the press and the forging tools used.

Would you like to know more about our forging presses?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for the new forging press

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding the forging press.