What types of Presses are there?

There are different types of Presses designed for different applications and work processes.

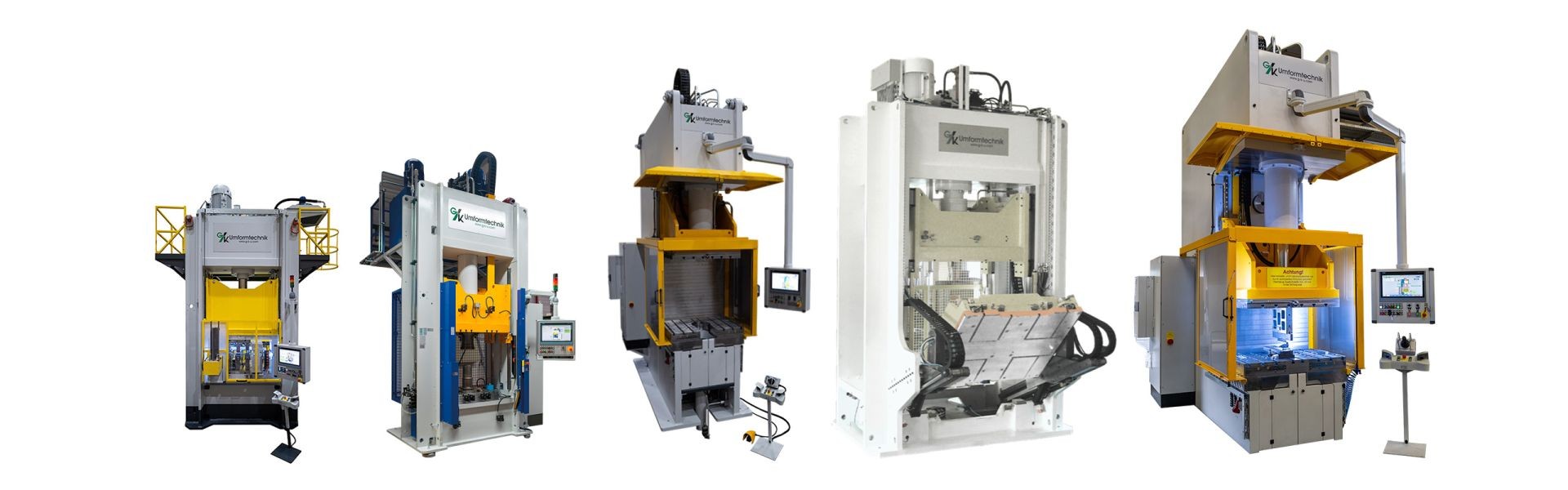

Presses are machines that play a crucial role in the manufacturing industry for shaping or processing materials. There are various designs of presses, each used according to application requirements and specific needs. Common types include the double column press, C-frame press, pillar press, and underframe press. Each of these press types has its own features and advantages, making them particularly suitable for certain tasks. In this article, we will take a closer look at these designs and explore their differences and areas of application.

Double Column Press

A double-column press is a type of hydraulic press where two vertical columns or stands form the machine frame.

C-frame Press

A C-frame press is a type of hydraulic press where the machine frame is shaped like the letter 'C'.

Column Press

A column press is a type of hydraulic press where the machine frame consists of one or more vertical columns or stands.

Downstroke Press

Underpresses are a specialized type of press used in metal forming and other industrial applications.

Special Design

For special requirements on a press, it is necessary to deviate from standard designs and develop a construction form tailored to the specific application.

Overview of customizable parameters of our Presses

Customizability

The press's ability to adapt to different shapes, sizes, or materials to meet production requirements.

Pressure force

This parameter indicates the maximum force (in tons) that the press can exert to shape or process the material.

Control system

The control system can be highly advanced, enabling programmability as well as integration into production lines.

Stroke length

The maximum vertical movement of the ram or pressure head (in mm) required for the respective production process.

Working speed

The speed (in strokes per minute or mm/s) at which the ram is lowered and raised to affect the production rate.

Do you want to know more about Press Designs?

We would be happy to discuss your task in a non-binding conversation:

- Which design is best suited for your application

- Concept development with drafts, layouts, budget. Press examples,

- Discussions about technical implementation options, space requirements, details and optimization of the offer phase

Come and talk to us!