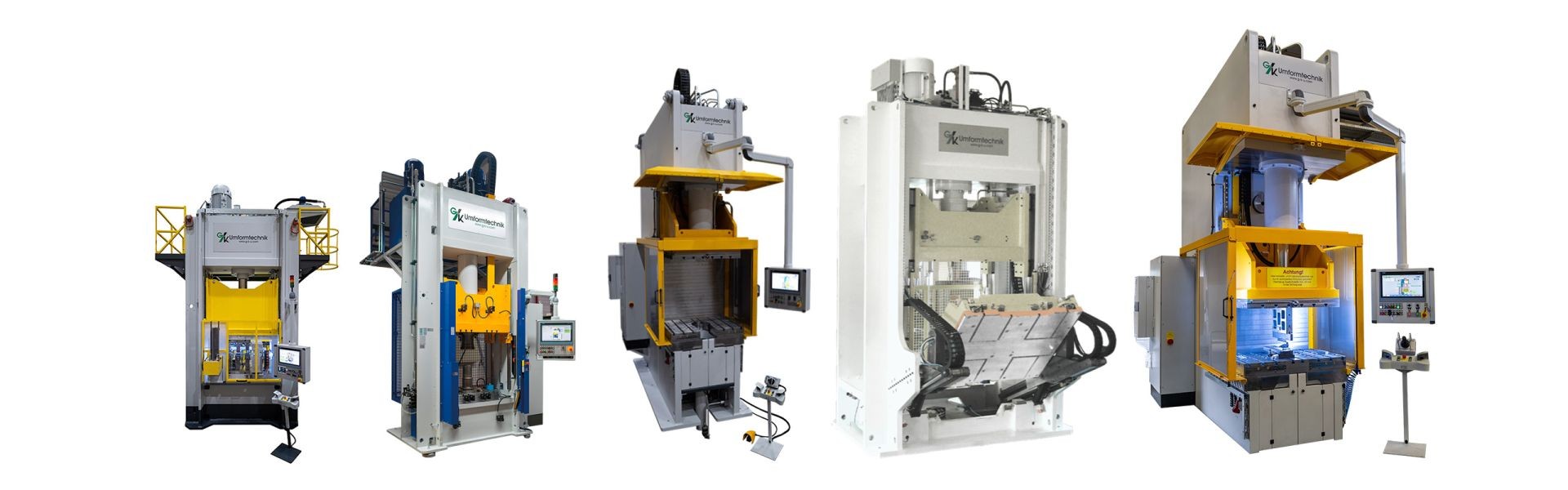

Customizable C-Frame Presses from G+K

What are C-frame presses

A C-frame press is a special type of forming machine that is used for various manufacturing processes such as punching, bending, embossing and deep drawing. The machine is characterised by its open C-shaped structure, which allows access to the work areas from three sides. This design facilitates the handling of large workpieces and complex machining processes.

Another feature is the high degree of customisability. C-frame presses can be customised, e.g. with drawing cushions, ejectors or sideshifters, to meet specific production requirements. Their robust construction ensures stability and precision, even under high pressure.

Customisation options include:

- Work surface adjustments, stroke height and force.

- Additional functions such as die cushions, ejectors and sideshifters for complex machining processes.

- Integration of automation technologies for efficient use in modern production environments.

- Safety functions such as safety devices and emergency stop systems for safe operation.

C-frame presses are particularly popular in the automotive industry, metalworking and other industries that require precise forming processes. They offer high versatility and efficiency, especially in automated production environments.

C-Frame Presses

Single-column presses offer excellent accessibility to the press table from three sides.

Application

This type of press is used for punching, bending, deep drawing, forming, pressing, embossing, straightening, calibrating, assembling, deburring, and more. The good accessibility of the press table also allows for the processing of large and bulky components.

These presses are used for manual loading, but can also be equipped with G+K automation components for large-scale production. Additional functions such as draw pads, ejectors, and side shifters are possible and implemented as needed.

Special Features

G+K C-frame presses have a robust construction made of welded steel plates, which are first annealed and then precisely machined. C-frame presses are offered with two types of ram guidance: the classic round column guidance with a focus on twist prevention, and a flat guidance with linear guides on the press wall and four tool carriages on the ram. Even though the C-frame press is geometrically less favorable due to its asymmetrical design, the strong design of G+K presses provides sufficient compensation for deflection.

Customizable Parameters of Our C-Frame Presses

Distance Between Uprights

The distance (in mm) between the two vertical uprights of the C-frame affects the maximum width of the material to be processed.

Work Surface

The size of the work surface (in mm x mm) where the material to be processed is placed.

Tool Change System

C-frame presses can feature a tool change system to facilitate the exchange of tools for different production requirements.

Safety Features

Modern C-frame presses are often equipped with various safety features, such as light curtains, emergency stop switches, and safety zones to prevent accidents.

Energy Efficiency

The energy consumption of the C-frame press can play a role, especially in terms of operating costs and environmental impact.

Do you want to learn more about our C-frame presses?

Gladly, we can discuss your specific case in a non-binding conversation. You can expect the following:

- Joint concept and discussion about the new single-column/C-frame press

- First sketches/layout of the new machine

- Clarification with design and operators

What is a C-Frame Press?

A C-frame, or single-column press, is a type of hydraulic press where the machine frame has the shape of the letter "C". The C-frame design provides an open structure for good accessibility and easy setup.