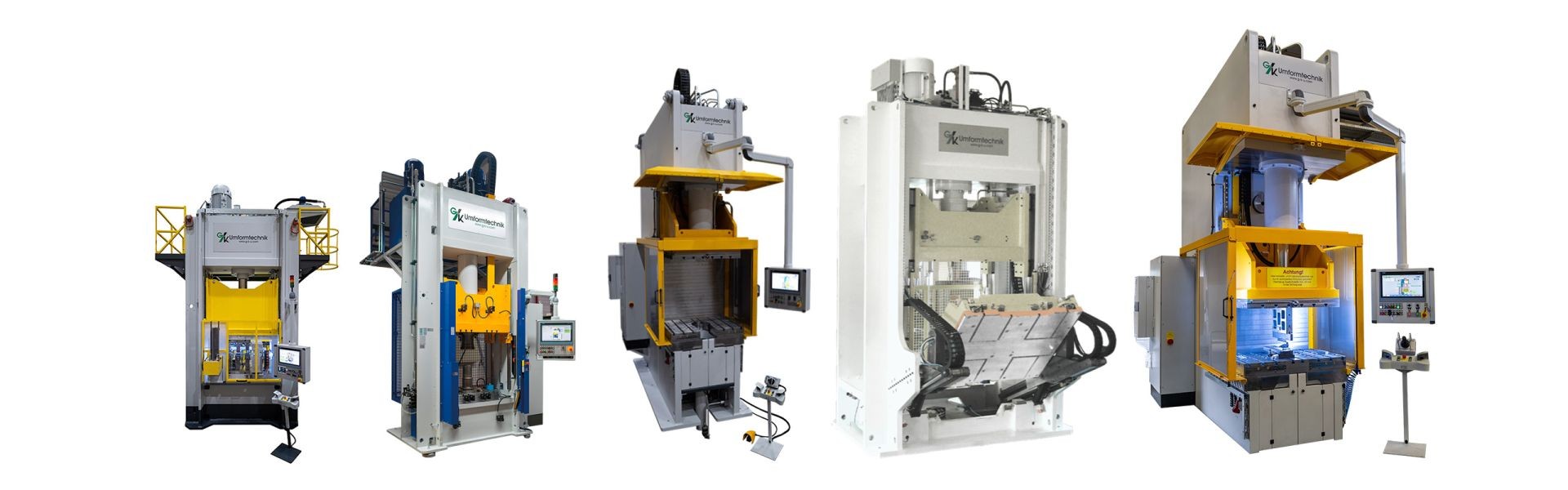

Customizable Hydraulic Embossing Press

What is a hydraulic Embossing Press?

A hydraulic Embossing Press is an industrial machine used in forming technology that employs hydraulic force to emboss inscriptions, patterns, symbols, or other designs onto workpieces. The stamping process involves applying pressure to a stamping tool to transfer the embossing into the material.

Hydraulic Embossing Press from G+K

Customizable hydraulic Embossing Presses are produced by us in collaboration with the customer.

Parameters of our hydraulic Embossing Presses

Pressing force

This parameter indicates the maximum force (in kN) that can be exerted by the press.

Type

Embossing Presses can be configured as single-column, double-column, or pillar presses.

Security

Depending on the type of machine equipment and the pressing speed, the control and safety devices are individually configured according to the current safety guidelines for Embossing Presses.

Stroke, installation height, table and ram dimensions

The geometric parameters of the bending press can be precisely configured according to requirements using the G+K modular system.

Rush and working speed

The speed of the press is tailored to the expected tasks. From the precise burnishing press to the embossing press. From the force-intensive drawing press, the robust Embossing Press, to the forging and impact press.

Control system

The operating modes of a bending press can be manual, semi-automatic, or fully automatic. These variants affect both the user-friendliness and the level of automation of the machine, as well as the required use of safety technology.

Tool changing systems

It is recommended to use insertion pads, ball or roller rail elements, and possibly a clamping pin in the ram, T-slots in the table and in the ram, or centering pins on the table surface for tool changes. Hydraulic clamps ensure a secure and swift fixation of the tools.

Energy efficiency

A environmentally friendly and material-saving hydraulic drive is integrated. The control system includes a menu that allows for automatic shutdown of the machine after X minutes.

Safety devices

Hydraulic Embossing Presses are always equipped with appropriate and necessary safety features, such as two-hand controls, light barriers, safety doors, emergency stop buttons, and safety zones with protective enclosures, to prevent accidents.

Adaptation of tools

The table and ram can be equipped with a custom grooving or drilling pattern to ensure comprehensive compatibility with a variety of existing tools.

How do you find the optimal Embossing Press?

Just a few steps to your offer:

- Task and specifications

- First sketches of the new machine, layouts

- Discussions with design and manufacturing experts

- Budget estimate

Please feel free to contact me to arrange an appointment regarding the Embossing Press.