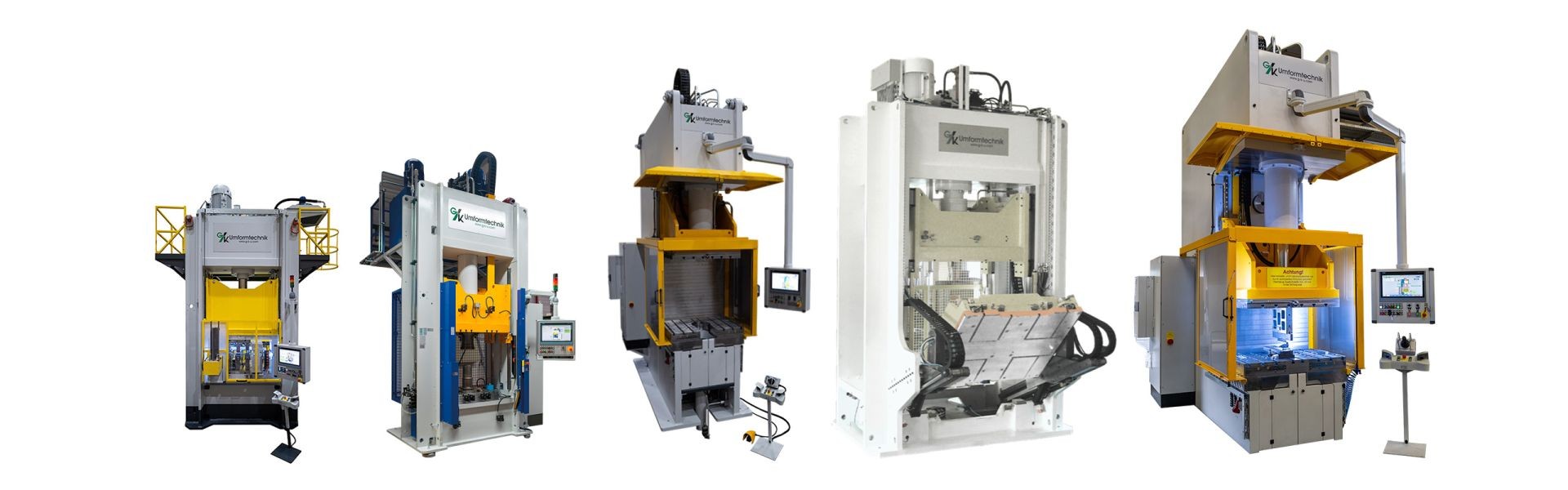

Customizable hydraulic step press

What is a hydraulic step press?

A hydraulic stamping press, also known as a step-stamping press, is an industrial machine that uses hydraulic power to process workpieces in successive steps. The process involves the use of step tools that act on the workpiece sequentially. This type of press is commonly used for forming processes where the workpiece is gradually altered to achieve the desired shape or dimensions.

Customizable parameters of our hydraulic transfer presses

Working speed

The speed (in strokes per minute) at which the ram moves up and down affects the production rate of the stamping press.

Number of steps or tools

The number of stages or tools integrated into a stamping press affects the versatility and scope of processing that the press can perform simultaneously.

Tool change system

Some hydraulic stamping presses are equipped with automated tool change systems to facilitate the exchange of tools between forming stations.

Energy consumption

The energy consumption of the hydraulic stamping press can be a factor, especially when it comes to operating costs and environmental impact.

Control system

The control system can be manual, semi-automatic, or fully automatic, and it affects the operability and the level of automation of the stamping press.

Security features

Modern hydraulic stamping presses are often equipped with various safety features, such as light barriers, emergency stop buttons, and safety zones, to prevent accidents.

Would you like to learn more about our step presses?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for the new step press

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding the step press.