Custom-made mechanical engineering - Made in Germany

Over 20 years of experience in the field of forming technology

G+K as a manufacturer of systems for versatile applications

We bring your ideas to life – Custom-made in Germany with extensive experience and know-how in the field of forming technology, our goal is to fulfill our customers' wishes in the best possible way.

Our machines represent German craftsmanship: maximum reliability and efficiency. We offer comprehensive solutions for forming technology and combine our expertise to develop the most effective solution for each challenge – following the principle: as simple as possible, as complex as necessary.

Thanks to our extensive expertise in mechanical engineering and automation, we ensure that interface problems do not arise in the first place.

As a flexible and resourceful problem solver, we have already served a wide variety of markets, including:

- Automotive supply industry

Metal processing industry

Aerospace

Construction industry

Textile industry

Automation/Robotics

Foundry industry

Energy and environmental technology

Joining technology

Plastics technology

The courage to take unconventional paths

G+K's success results from a constant pursuit of perfection. Market-oriented solutions based on numerous successful installations guarantee our customers the highest level of cost-effectiveness. Additionally, G+K Forming Technology offers reliable, personal service and top-notch consulting in manufacturing technology.

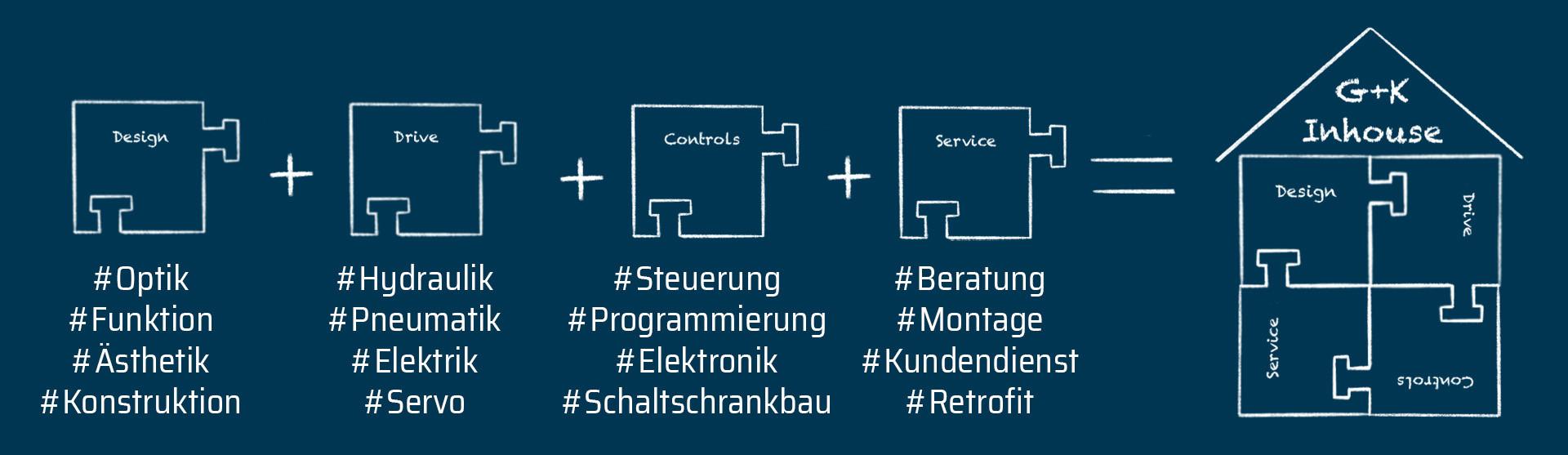

Our in-house concept

We have all important areas for the development and production of a machine in-house.

Company history

The company G+K Umformtechnik GmbH was founded on February 22, 2000, by Mr. Normen Gröschl and Dr. Michael Kunkel.

The initial staff included personnel with 30 years of experience in press construction and forming technology. This allowed the young company to assert itself from the very beginning against well-known competitors.

As a provisional first company headquarters, the company chose the address Königsberger Straße 14 in Niedernberg. Even the first major projects demonstrated the innovative character of the company. These include fully automated machines for stamping out step bushes in aluminum wheels, as well as a facility capable of bending shift forks for car gearboxes with previously unmatched precision on a large-scale production basis. Additionally, a decoiler for coil weights of 30 tons was already implemented by G+K in the first business year.

Due to the dynamic and upward trajectory of the company's development, it was possible and necessary to move to larger business premises at Nordring 68 in Niedernberg after just one year. This property is now owned by the company.

A manufacturing and technology network exists with Rudolf Kunkel Maschinenbau GmbH in Bessenbach.

Press reports

Downloads