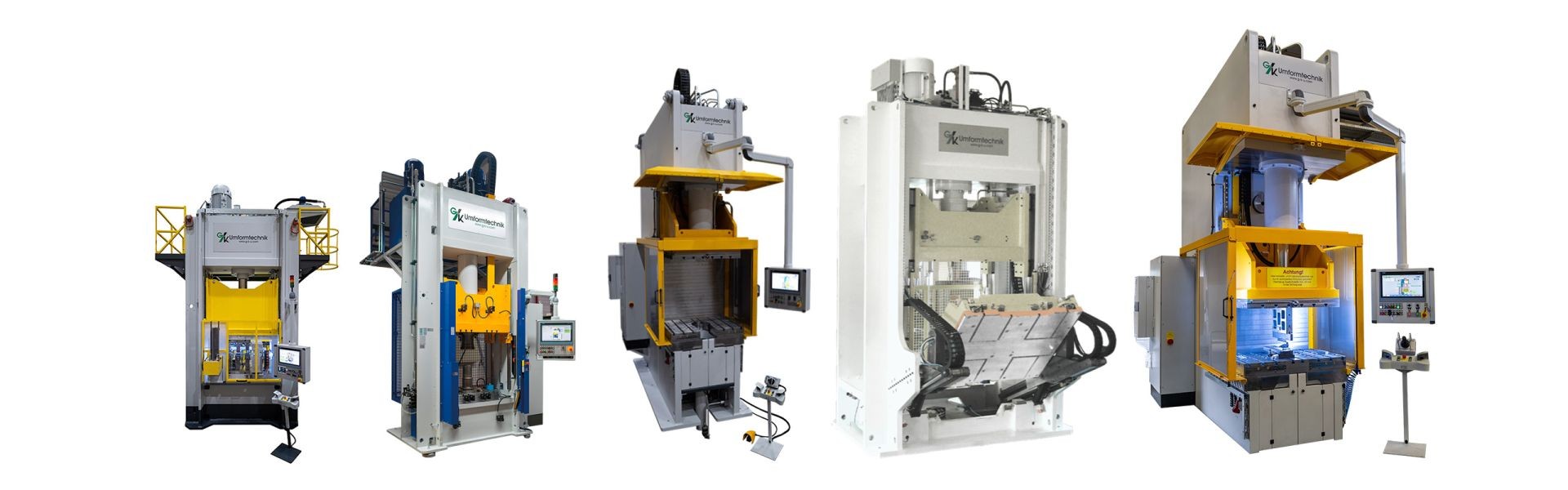

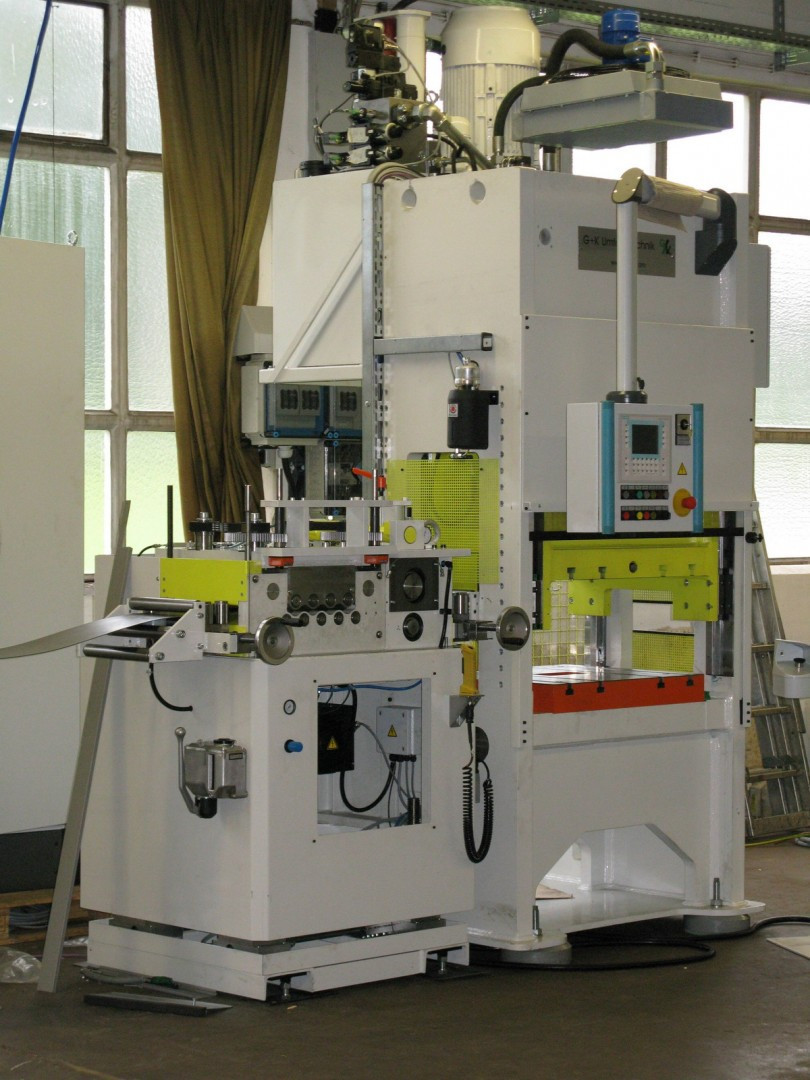

Customizable Hydraulic Special Application Presses

What are special application hydraulic presses?

Hydraulic presses for special applications are specialized industrial machines designed for specific, non-routine applications or processes. These presses are often customized or modified to meet the unique requirements of particular industries or tasks.

Special presses

Special presses are machines that are tailored to specifically defined manufacturing technologies.

Application area of the special presses

Special presses are used for

Stamping

Bending

Forms

Deep drawing

Press

Embossing

Straighten

Calibrate

Add

Extrusion

Wheel punching

Deburring sprue

and much more

The primary use of special presses is in the field of high-volume production in an industrial environment. This includes automotive, consumer electronics, white goods industry, and others.

Control of special presses

Siemens S7-1500 series control panel Siemens Comfort Panel 19" or by individual arrangement.

Customizable parameters of our hydraulic presses for special applications

Pressure force

The maximum force (in tons) that the press can exert to meet the specific requirements of the application.

Stroke length

The maximum vertical movement of the ram or pressure head (in mm) required for the specific application.

Working speed

The speed (in mm/s) at which the plunger is lowered and raised to optimize the production process.

Work surface

The size of the working area (in mm x mm) on which the special materials or components are placed.

Tool change system

Some specialized presses may feature automated tool change systems to handle different tasks or materials.

Energy consumption

The energy consumption of the press can be a factor, especially when it comes to operating costs and environmental impacts.

Control system

The control system can be manual, semi-automatic, or fully automatic and is adapted to the specific requirements of the application.

Safety features

Depending on the specific hazards or requirements of the application, safety features may be implemented to prevent accidents.

Material compatibility

Some presses can be specifically designed for processing certain materials or material combinations.

Customizability

The press's ability to adapt to different shapes, sizes, or materials to meet the requirements of special applications.

Environmental conditions

Specialized presses can be designed for operation under specific environmental conditions, such as extreme temperatures or cleanroom conditions.

G+K Special Features

G+K has extensive and well-known references in the field of special presses.

Speed, flexibility and innovation characterize G+K production plants, as well as a dash of the latest technology in every project.

Give us your specifications - and we will offer you a solution according to your requirements in the short term.

Would you like to learn more about our presses for special applications?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for the new press for special applications

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding presses for special applications.