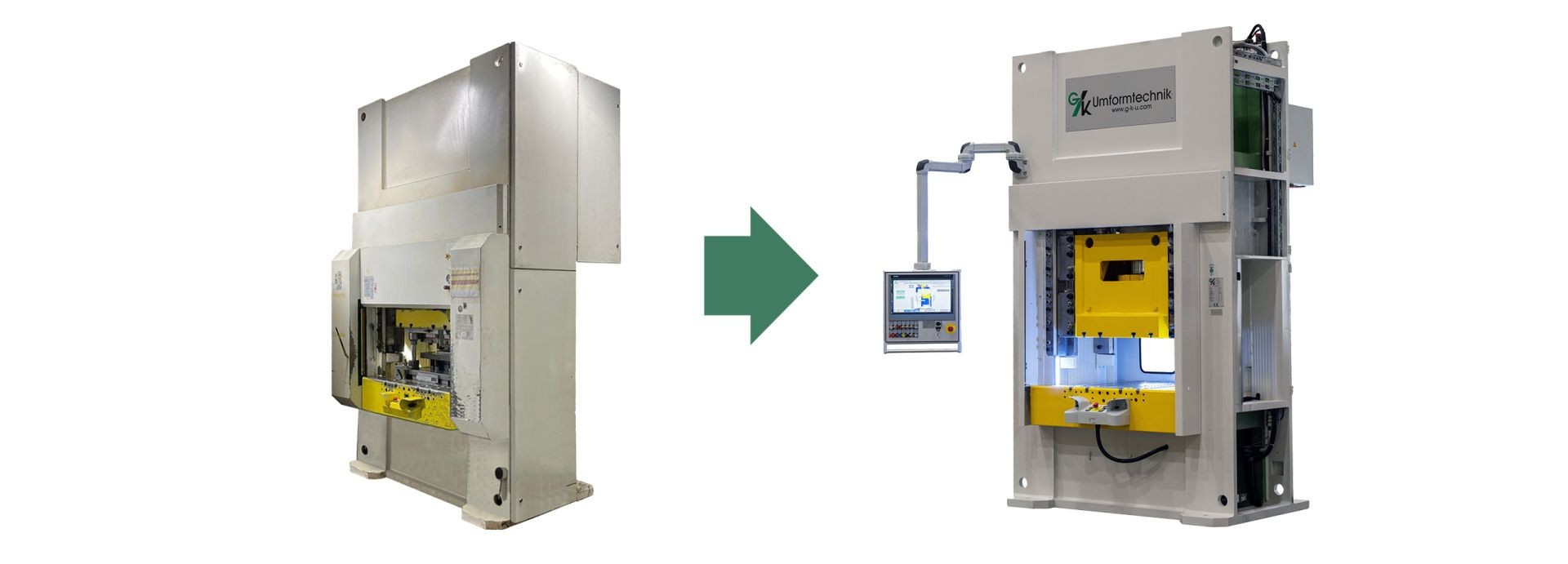

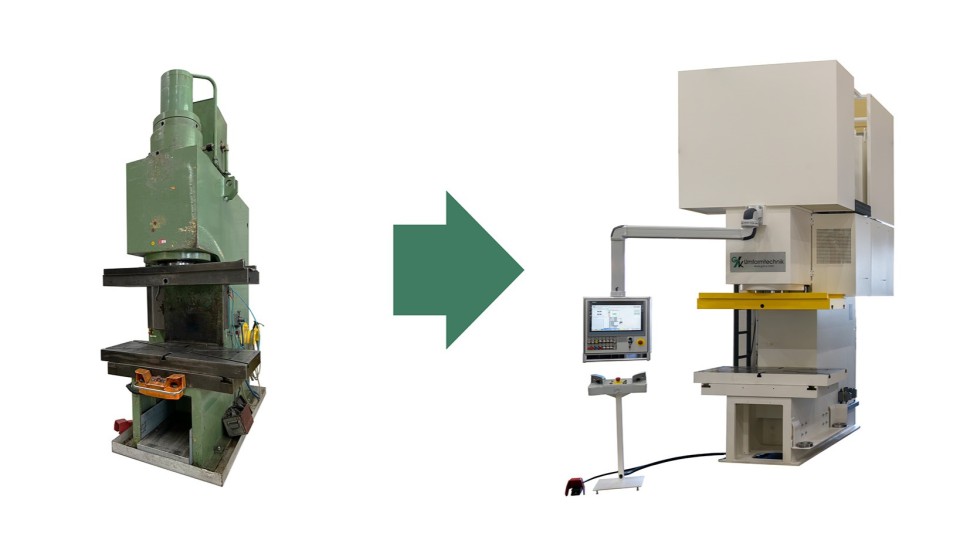

Retrofit (machine overhaul)

We transform old industrial plants into high-quality production technology.

There is no 'old machine' that G+K cannot bring up to the latest industrial standards to increase the efficiency of your production. With our retrofit (machine overhaul) service, we offer you the opportunity to upgrade your old equipment to the latest technology—tailored exactly to your requirements and often at a fraction of the cost of a new purchase. Proven but outdated technology does not always need to be replaced; we retain what has proven effective and make it secure for the future.

Since the founding of G+K Umformtechnik over 20 years ago, we have been performing retrofits in machine engineering. Our services are not limited to presses; we also offer modernization for old straightening machines, reels, strip feeders, and other types of industrial equipment. With our extensive experience in this field and our comprehensive technical expertise, we are a global point of contact for all matters related to old industrial equipment.

The advantages of a retrofit (machine overhaul)

- High cost efficiency: Lower investment costs compared to a new purchase

- Performance Enhancement: Increased productivity and energy savings

- New Automation Possibilities: Integration of modern technologies for improved processes

- Seamless Integration: Adapts to existing production lines without major modifications

- Increased System Reliability: High-quality new components ensure reliable operation

- Reduced Downtime: Shorter project turnaround time compared to new purchases

- Safety: Safety technology that meets the latest requirements and standards

- User-Friendliness: Easy operation with large screens and straightforward control systems

- Reduced Training Effort: Since the machine's base remains familiar, training requirements for staff are lower

The G+K Retrofit: Our services, your advantages

Retrofitting old presses and straightening machines offers a variety of benefits that impact both the performance of the machines and the economic and ecological aspects.

Our retrofitting services include:

Conducting a thorough complete cleaning of your stamping press as well as preparing the tank to ensure flawless operation.

2. Professional disassembly and reassemblyCareful dismantling and subsequent assembly of all machine components by trained G+K personnel.

3. Inspection and overhaul of hydraulic cylinders

Existing hydraulic cylinders are inspected and resealed if necessary to ensure reliable performance.

Depending on the requirements, we also offer a complete renewal of the cylinders.

4. Replacement of guide columns and bushings

If needed, we offer the replacement of the guide columns to increase the installation height and the renewal of the guides and bushings, adjusted to the new specifications.

5. Modernization of hydraulic systems

Integration of the latest hydraulic technology with the capability for precise control of cylinder movements, increased working speed, and more.

6. Clear reinstallation of electrical components

Professional installation of all electrical components, including wiring, control cabinets, and controls, to enhance reliability, safety, and maintenance accessibility.

7. Integration of current control technology

Integration of a current Siemens control system, which, in conjunction with a new, larger display, offers new automation possibilities and a more user-friendly operation.

8. Implementation of energy-efficient drive systems

Use of modern, energy-efficient drive technologies such as variable-speed drives to reduce energy consumption and increase sustainability.

9. Upgrade of security technology to the latest state

Renewal or renovation of all safety measures to meet current safety requirements while also providing a high level of user-friendliness.

10. Comprehensive training and reliable on-site support from our staff

We ensure that the operators of the modernized system receive optimal training from us, and that you receive reliable and swift support from our service staff in any future service or repair situation.

Overall, G+K offers a cost-effective way to enhance the performance, efficiency, safety, and user-friendliness of your existing equipment while extending the lifespan of the machines through retrofitting old presses, straightening machines, and other industrial equipment.

F.A.Q

Yes, our retrofit solutions are flexible and can be adapted to seamlessly integrate with your existing press. We carefully analyze your machine and develop the necessary modifications to ensure perfect integration of the retrofit components.

Retrofit solutions are generally significantly more cost-effective than purchasing a new press, while providing comparable or even improved performance. Additionally, retrofit can help you save costs in the long term, for example, through reduced energy and maintenance expenses.

By integrating energy-efficient drive technologies and control systems, the energy consumption of your press is significantly reduced.

Yes, by replacing or reworking mechanical components, we can increase the precision of your machine. This includes, for example, the re-grinding of guides or the installation of more precise ball screws.

Yes, through retrofitting, essential components are modernized, which significantly extends the lifespan of your press. The reliability and fail-safety of your machine are also improved by replacing and upgrading critical systems.

After a retrofit, maintenance efforts are often reduced, as modernized machines are less prone to breakdowns.

Yes, we ensure that your stamping press complies with all current safety and industry standards after the retrofit. Additionally, we improve the operability and ergonomics of your machine to optimize working conditions.

The duration of a retrofit depends on the complexity of the project, but we always work to keep downtime to a minimum. We plan the retrofit process to ensure that your production is disrupted as little as possible.

In addition to the warranty on our retrofits, our experienced team of service technicians is available for any questions and concerns you may have, whether it's a malfunction, upcoming maintenance, or a modification of the system as per your request.

Find out how our retrofit can improve your production

We would be happy to discuss your specific concerns in a non-binding conversation. You can expect the following:

- An initial concept proposal for the efficient implementation of your retrofit

- Creative ideas for useful extensions and additions

- Examples of successfully completed retrofit projects that match your goals

- Our comprehensive know-how as a basis for your decisions

Please feel free to contact us!