Customizable belt systems from G+K

What are conveyor systems?

Belt systems are industrial conveyor systems designed to transport materials in the form of belts, straps, or bands from one point to another. These systems play a crucial role in various industries and production processes, as they enable the efficient transportation of raw materials, semi-finished products, or finished goods.

Structure and functionality:

A conveyor system typically consists of a conveyor belt mounted on rollers or drums and driven by a motor. The conveyor belt is made of a flexible, durable material, which can be rubber, plastic, or metal, depending on the application's requirements. The material is placed on the conveyor belt and is transported to the desired destination by the rotation of the drums or rollers. In some cases, conveyor systems may also be equipped with side guides, alignment systems, or other additional features to ensure that the material remains in the desired position.

Overview of conveyor systems

G+K is your competent partner for strip processing systems for all industrial applications, service centers, and transverse cutting systems for all metals. Our exceptional expertise in hydraulics allows us to build machines that meet quality requirements at the highest level. The decades of experience G+K has acquired in straightening is reflected in a wide range of different designs and sizes.

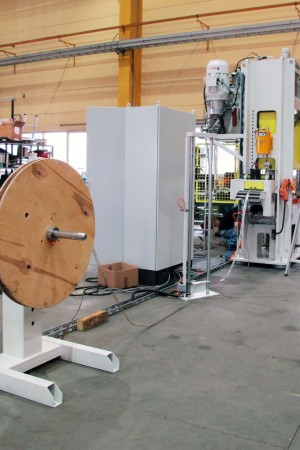

Our conveyor systems

Cut-to-length lines

Cut-to-length lines copper

Reels

Feeders

Our customizable belt systems process material thicknesses from 0.05 mm to 10 mm. Furthermore, the processed material width ranges from 150 mm to 2000 mm or more on request.

On G+K strip processing lines, a wide variety of materials can be processed, from highly sensitive surfaces to heavy plate.

Customizable parameters of our conveyor systems

Band type and material

The material and type of the conveyor belt influence its load capacity, wear resistance, and application possibilities. There are various types of conveyor belts, including belt conveyors, roller conveyors, chain conveyors, and others.

Load capacity

The load capacity of a conveyor belt indicates how much weight it can transport without becoming overloaded.

Bandwidth

The width of the conveyor belt determines how much material it can hold and transport. The belt width is typically measured in millimeters.

Speed

The conveyor belt speed determines how quickly the material is transported from one point to another. It is measured in meters per second (m/s) or other units of speed.

Drive system

The drive system can be electric, hydraulic, or mechanical. It affects the performance and controllability of the strip line.

Control system

Modern strip processing systems can be equipped with advanced control systems that can monitor and control speed, direction, and other parameters.

Resilience

The band system must be capable of handling the load and shock loads caused by the transported material.

Ease of maintenance

The accessibility and ease of maintenance of the strip line influence the maintenance efficiency.

Security features

Belt systems should be equipped with safety features such as emergency stop buttons, protective covers, and overload sensors to ensure operator safety.

Deflection and drive units

The type and arrangement of the deflection and drive units influence the direction and control of the conveyor belt.

Belt slopes and inclination angles

Belt inclinations and angles can be adjusted to meet the specific requirements of material handling.

Additional equipment

Conveyor systems can be equipped with additional features such as side guides, skirts, inspection openings, or cleaning systems.

Would you like to find out more about our conveyor systems?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint conceptual discussion for the new conveyor system

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding conveyor systems.