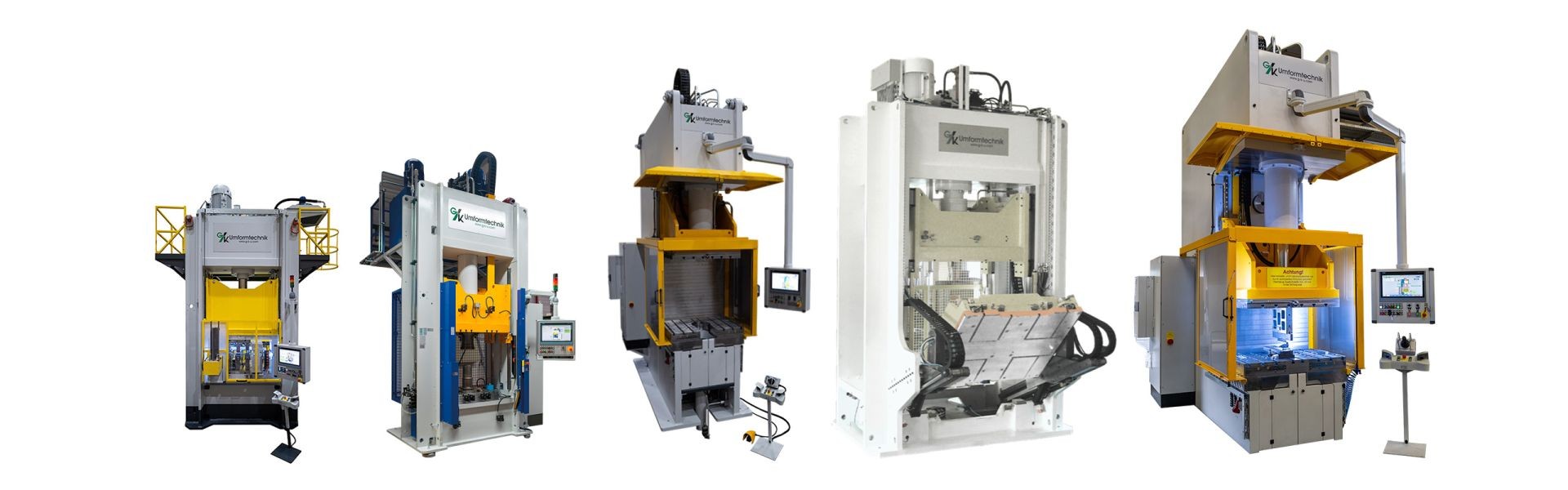

Hydraulic Presses from G+K for Industrial Projects

Überblick Hydraulische Pressen

Eine hydraulische Presse ist eine industriell eingesetzte Maschine der Umformtechnik. Diese Pressen werden in einer Vielzahl von industriellen Anwendungen eingesetzt, um Material zu formen, tiefzuziehen, zu biegen, zu stanzen, zu pressen oder anderweitig spanlos zu bearbeiten. Hier sind grundlegende Informationen über hydraulische Pressen:

Aufbau und Funktionsweise

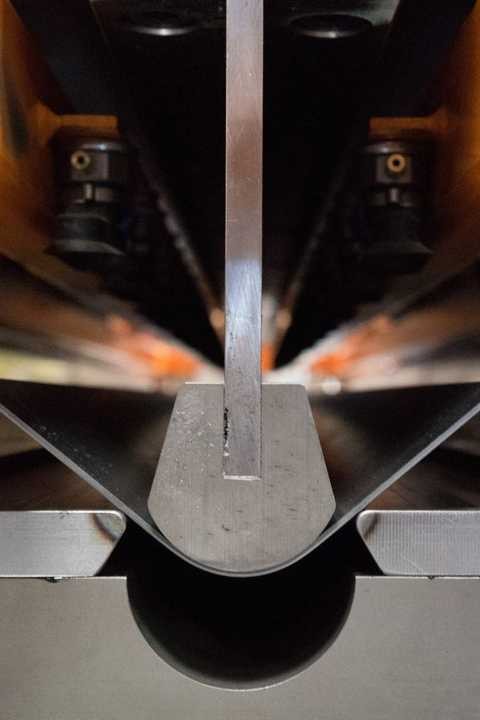

Eine hydraulische Presse besteht typischerweise aus einem Zylindersystem, einem Hydrauliksystem und einem Rahmen. Das Hydrauliksystem erzeugt Druck, der auf den Kolben und damit die Kolbenstange wirkt. Diese wiederum überträgt die entstehende Kraft auf den Stößel. Mittels eines geeigneten Werkzeugs zwischen Stößel und Tisch wirkt die Kraft dann unmittelbar auf das zu bearbeitende Werkstück. Somit können in diesen Anlagen Umform- und Bearbeitungsprozesse aller Art von Einzel- bis hin zur Massenfertigung durchgeführt werden.

What is special about our hydraulic G+K presses

Power and speed tailored to the industry’s leading products

G+K has core competencies in mechanics, electrics, electronics, and hydraulics for industrial projects in the field of hydraulic presses. Our expertise ensures that each machine undergoes individualized performance optimization, which also meets the highest environmental standards. Our range of hydraulic presses includes everything from inherently small assembly components to the classic stamping or drawing press, and up to forging presses with over 30,000 kN of pressing force.

For every conceivable application, custom-made hydraulic presses are configured together with you in the exact design that suits your needs. G+K delivers the necessary press expertise for every use and every project.

This ensures perfect coordination between the production plant and the end product.

Our hydraulic press core competence

Mechanics

Durable, robust construction for precision in the final products and stable production processes.

Electrics

own control cabinet construction and electrical design

Electronics

Designed for the future - for intelligent and fast control processes

Hydraulics

gigantic forces - precisely dosed

Individual hydraulic presses for every task

Depending on the application, G+K builds the appropriate press. The design can also be asymmetrical or made in special sizes for unique applications. G+K masters all conceivable design forms. Special emphasis is placed on good accessibility, maintenance friendliness, and ergonomic work conditions.

G+K presses set standards in occupational safety, user-friendliness and ergonomics

G+K hydraulic presses are durable capital goods. That’s why G+K places particular emphasis on generous sizing, in-house manufacturing, components from renowned brand manufacturers, and easy access to technical units. As a result, these machines require minimal maintenance, which is especially advantageous given that they are used worldwide.

Key data of our presses

Pressure force

The maximum hydraulic force that the press can generate. It is given in kilonewtons (kN).

Stroke

The maximum stroke, which indicates how far the piston can move between the upper and lower dead centers. The distance between the piston in the upper dead center and the table is called the installation height. Installation height, stroke, and table size are the key dimensions for the tools that can be used.

Work surface/table size and ram surface

The dimensions of the work surface, table, or the ram to which the tool is attached. They are specified in width by depth.

Speed

Maximum possible speed at which the plunger moves. It is usually measured in millimeters per second (mm/sec). It is important to distinguish between rapid traverse (with reduced force), working speed (with full pressure), and retracting speed.

Safe speed

Presses are subject to high safety requirements. The safe operation of a press is possible at speeds below 10 mm/sec, corresponding to 0.6 m/min. If this speed is safely undershot, elaborate safety circuits can be avoided.

Type

Presses can also be distinguished by the geometric shape of their frames. There are single-column presses, also known as C-frame or swan-neck presses, double-column presses, also referred to as H-presses, as well as three-column and four-column presses. Depending on the structure, the machine's bending or elongation varies, which in turn affects the achievable accuracy of the end products and the wear of tools. The machine design also impacts accessibility to the press table, setup times, and necessary safety elements, such as contactless protective devices.

Control

G+K only uses electronic and hydraulic components from Siemens and Parker to ensure absolute safety, reliability and durability.

Operating mode

G+K can design presses for all conceivable operating conditions. This means that there can be presses that can switch from hot operation to manual loading operation, conveyor belt operation, and then to manual sample production—simply by changing the operating mode and activating the necessary safety devices.

Security

Hydraulic presses must have precisely defined safety features and meet requirements according to DIN EN ISO 16092 Part 3, Hydraulic Presses. Based on the European Machinery Directive, there are numerous national and international standards that must be adhered to in order to carry out a valid CE marking before the machine can be placed on the market.

Ease of maintenance

G+K knows the concerns and needs of its customers from years of experience. That is why great importance is placed on user-friendliness and ease of maintenance.

Drive system

Pressure build-up and movement of the ram occur primarily through the conversion of hydraulic energy. However, there are also presses that work by means of mechanical or pneumatic power transmission.

Press stand

The structure of the press influences the accuracy as well as the stability and resilience of the machine. It is also a decisive factor for the usability of tools and their wear.

Was ist noch im Zusammenhang mit Hydraulischen Pressen interessant?

- Arten von hydraulischen Pressen (z. B. C-Rahmen-Presse, H-Rahmen-Presse, Säulenpresse)

- Anwendungen von hydraulischen Pressen (z. B. Metallumformung, Kunststoffverarbeitung, Holzbearbeitung)

- Hersteller von hydraulischen Pressen

- Preise und Kosten von hydraulischen Pressen

- Funktionsweise von hydraulischen Pressen

- Wartung und Reparatur von hydraulischen Pressen

- Bewertungen und Vergleiche verschiedener hydraulischer Pressenmodelle

- Verfügbare Größen und Kapazitäten von hydraulischen Pressen

- Sicherheitsrichtlinien für den Betrieb von hydraulischen Pressen

- Neuigkeiten und Entwicklungen in der hydraulischen Pressentechnologie.

How do you find a suitable G+K press?

We would be happy to discuss your requirements in more detail in a non-binding discussion:

- Analysis of your task based on drawings, sketches, specifications, descriptions

Concept development with drafts, layouts, budget

Discussions about technical implementation options, details, optimization

Offer phase

Come and talk to us!