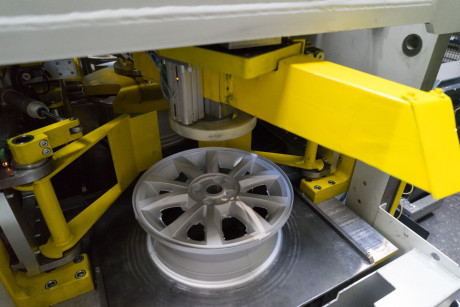

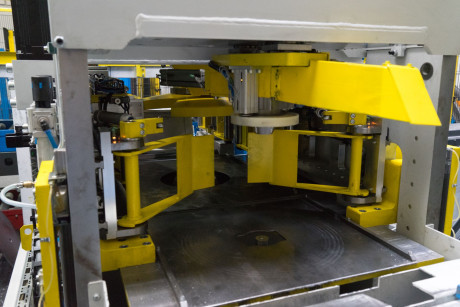

Reliable wheel drilling machines from G+K

Wheel drilling machines from G+K are used worldwide and are distinguished by their quality and high reliability.

The core of our machines consists of highly precise drilling spindles that are robust enough for demanding operating conditions.

Our reliable wheel drilling machine also features the following:

- Clean wheels after the drilling process because uncontrolled chip ejection is prevented by a protective bell.

- The wheels are preserved because they are not completely drilled through, and the gate is removed using a 'light stamping' process. As a result, there are no stresses in the structure.

- Recycling of clean aluminum chips through immediate remelting is possible.

- By using minimal quantity lubrication, the chips remain dry and clean.

- A separation of chips and scrap, which may be equipped with a sieve, is possible.

- The cycle time from wheel to wheel is <20 sec.

- A chaotic manufacturing process is made possible by the adaptive center alignment. The machine performs automatic drill depth measurement.

- The system is very compact (6.25 m³) and can be integrated into existing setups with additional drilling machines or stamping presses.

- The entire processing cycle is characterized by high energy efficiency.

Video wheel drilling machine

Would you like to know more about our wheel drilling machine?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint concept discussion for your wheel drilling machine

- Clarification of which rims should be processed

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding the wheel drilling machine.