Customizable Coilers

What are recoilers?

Recoilers are industrial machines designed to wind or unwind strip material, wire, or other flexible materials. They play a crucial role in metalworking, wire production, cable manufacturing, sheet processing, and other applications. Recoilers are used across various industries, including the metal industry, electronics, construction, and more.

Power and speed tailored to industry-leading products

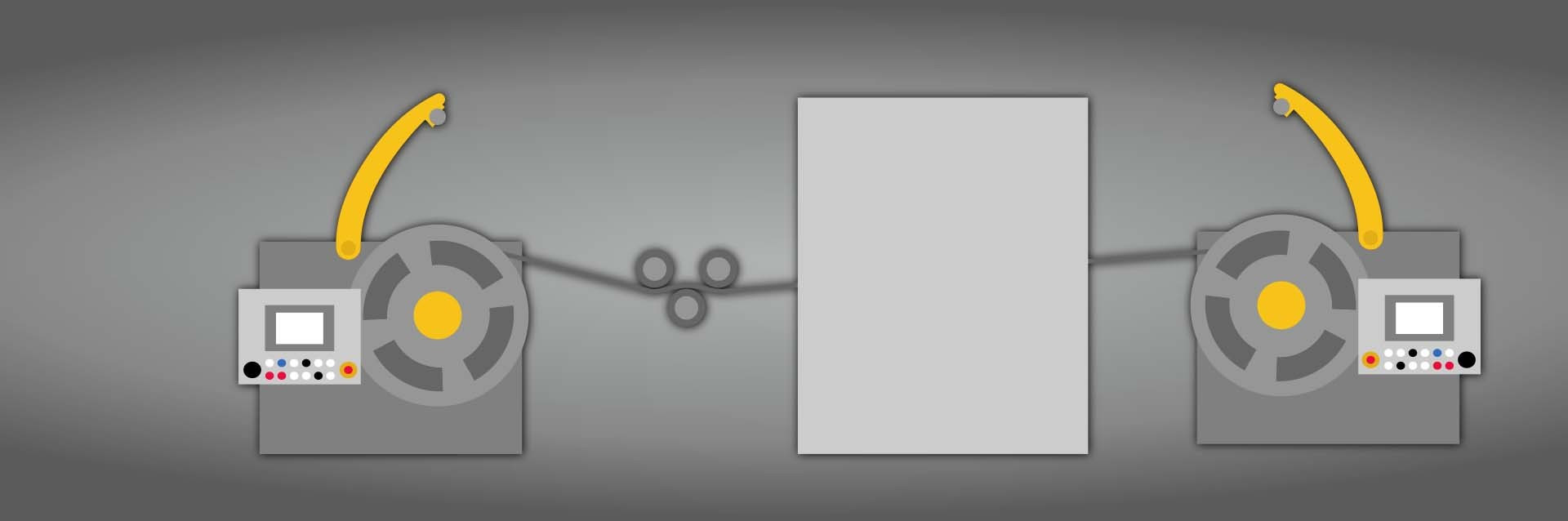

Overview of our customizable reel unwinders and winders

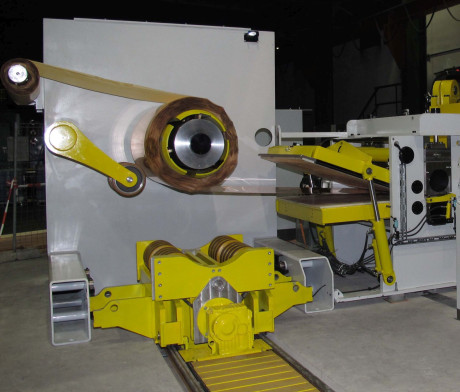

Maximum coil weight from 50 kg to 32 tons

Coil widths from 150 to 2200 mm

Coil diameters according to all common standards (e.g., 400 mm, 500 mm, 600 mm)

Winding force up to 50 kN

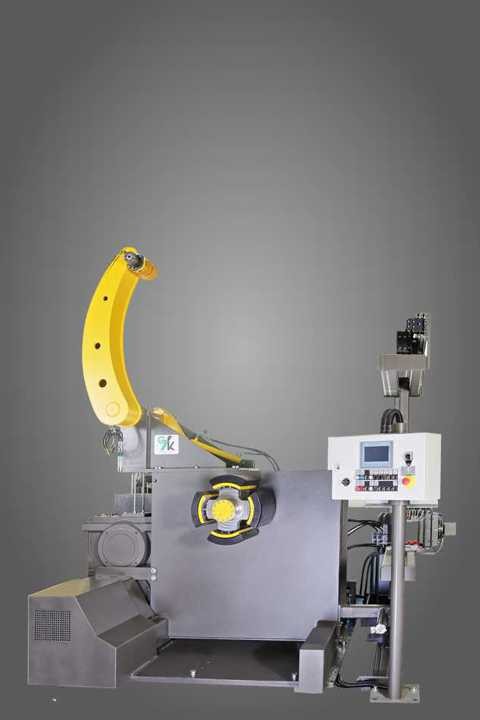

G+K has core competencies in mechanics, electrical engineering, electronics, and hydraulics. Our expertise ensures performance optimization for each machine, meeting the highest environmental standards. Our range of unwinders and winders includes compact models as well as large units.

For your application, unwinders and winders are configured in the exact variant that suits your needs, with G+K providing the necessary winding expertise.

This achieves the perfect alignment of production equipment and end product.

Customizable Parameters of Our Coilers

Load Capacity

The load capacity of a coiler indicates how much material it can handle or dispense before reaching its limits. It is often measured in tons or kilograms.

Reel Diameter

The maximum diameter of the reel that the coiler can handle or dispense.

Material Width

The maximum width of the material that the coiler can accommodate or dispense.

Adjustability

The ability to adjust the coiler for different material widths to meet various requirements.

Drive System

The drive system can be mechanical or electric. Electric drives often provide more precise control options.

Speed Control

The ability to regulate the speed of the coiler's drive to match the needs of the production process.

Automation

Modern coilers can be equipped with automated control systems that monitor material flow and optimize the process.

Braking System

An effective braking system is important to control the material's speed during the winding or unwinding process.

Safety Features

Coilers can include safety features such as emergency stop buttons or protective covers to ensure operator safety.

Material Tension Control

The ability to control the material's tension during the winding or unwinding process to ensure even winding.

Safety Clutch

A safety clutch can be used to prevent overloads and protect the material from damage.

Operating Mode

Coilers can operate in manual, semi-automatic, or fully automatic modes, depending on application requirements.

Winding Direction

The ability to change the winding direction to meet process requirements.

Would you like to learn more about our reels?

We'd be happy to discuss your specific case in a non-binding conversation. Here’s what you can expect:

A joint conceptual discussion for the new reel

Initial sketches of the new machine

Conversations with design and manufacturing teams

Access to confidential videos

Feel free to contact me to schedule an appointment regarding reels.