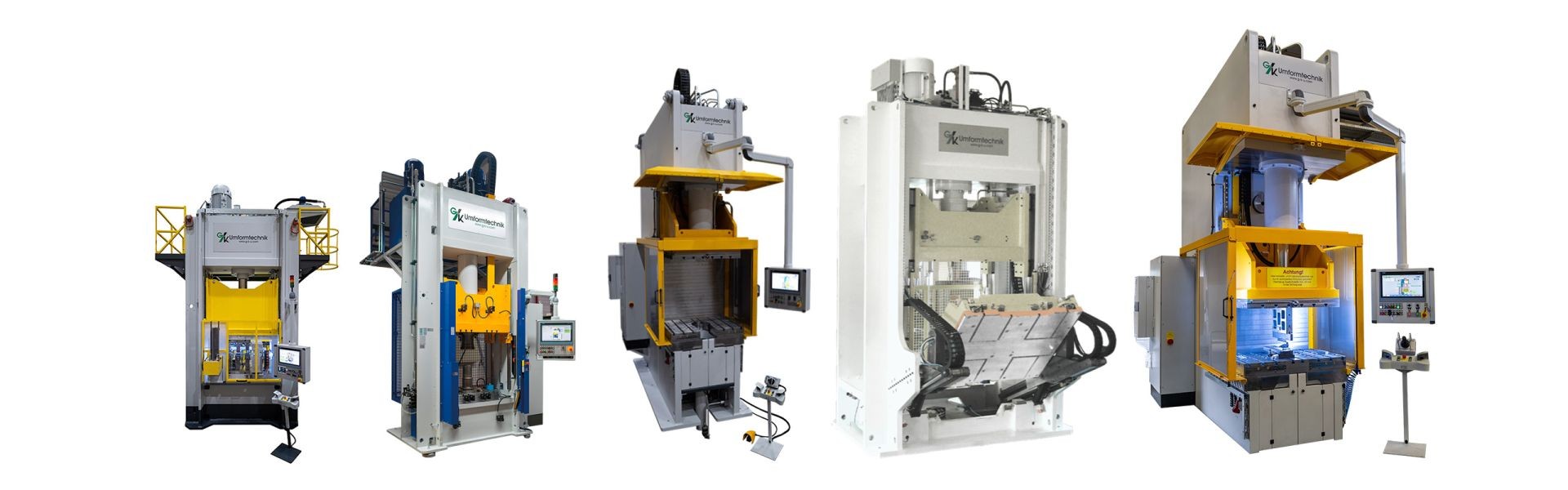

Robust double-column presses from G+K

What is a double-column press?

A double-column press, also known as a two-column press, is a type of hydraulic press where two vertical, robust columns on the left and right of the table and headplate form the machine frame. The double-column press is the most widely used due to its symmetry and its ability to withstand high forces.

Double-Column Press

The double-column design is the classic structure of a hydraulic press. The symmetry of the H-shape ensures stability, precision, and optimized force distribution.

Application Areas

Double-column presses are used for stamping, bending, forming, deep drawing, pressing, embossing, straightening, calibrating, joining, extrusion, and much more. These presses are perfectly suited for production processes using progressive dies. They can be used for manual loading but are mainly employed with G+K automation modules for large-scale series production. Additional functions include drawing cushions, ejectors, and side slides.

G+K Special Features

G+K double-column presses, in combination with G+K coil feeding lines, offer unbeatable competitive advantages in the efficient production of parts made from rolled metal semi-finished products. The mechanical structure of a G+K double-column press consists of a massive steel welded construction, annealed and precisely machined. The accuracy requirements of press geometry, as specified by standards, are significantly exceeded. Precision linear guides with eight guide carriages ensure highly accurate ram movement.

Control System

Siemens S 7-1500 series, operating panel Siemens Comfort Panel 19".

Parameters of our Double-Column Presses

Force, Stroke Length, Installation Height

The basic sizes are press force and the dimensions between the top and bottom dead centers, as well as the distance between the bolster and the ram at the top dead center (TDC).

Table Size

Table width in mm x table depth in mm, the arrangement of the slots in the table and ram is relevant for the planned tools.

Blank Holder, Ejector, Cutting Impact Damper, Part Inspection

These options allow extended tool functions.

Speed

Fast approach speed, working stroke speed, and retraction speeds are defined during the initial press design.

Tool Change System

Using hanging supports and ball or roller guide elements significantly simplifies tool changes. Hydraulic clamping elements further reduce setup time.

Safety

Due to the design, the sides are closed off except for the openings for the strip feed. A safety door secures the rear part of the press. At the front, it is either a light curtain or a mechanical safety door that eliminates the risk of operator injury.

Integration of Coil Lines, Transfers

When the press is operated in conjunction with a coil line, the G+K control system provides optimal conditions for highly efficient work processes. For certain part geometries, a G+K transfer system may also be used.

Would you like to learn more about our double-column presses?

We would be happy to discuss your specific task:

- Your requirements, our concept

- Sketches and layouts, budget

- Discussions with practitioners from your company

- Our offer for you

Feel free to contact me to schedule an appointment.