Conveyor systems as cross-cutting systems

What is a cross-cutting system?

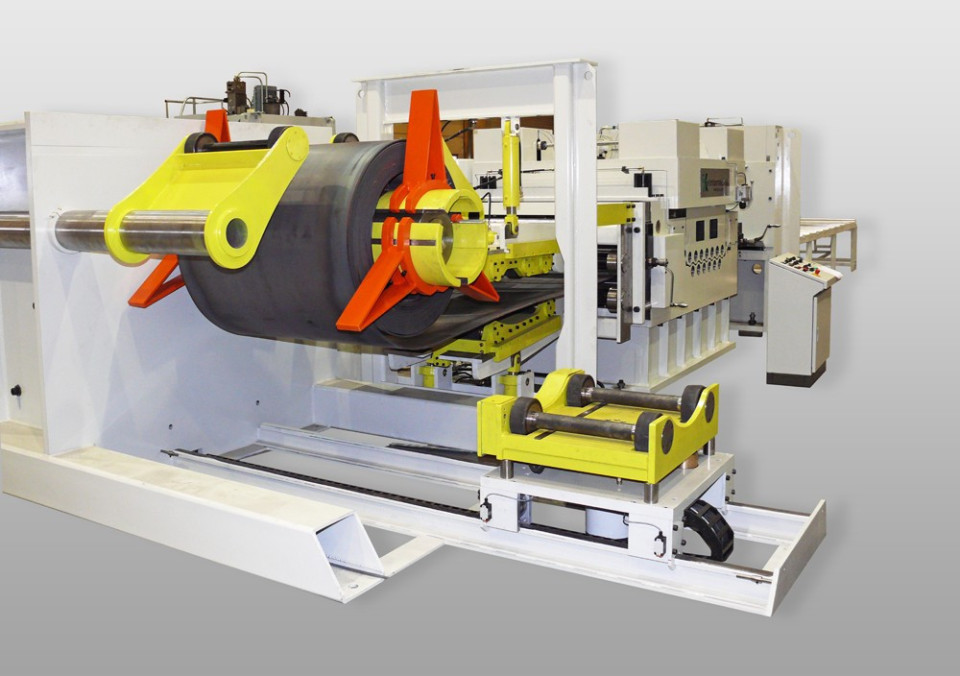

A cross-cutting line is a machine designed to cut coils (coil sheets) into longer strips or bands. These systems are frequently used in metal processing to cut large rolls of metal sheets or bands into narrower strips, which can then be used for further manufacturing processes.

Cut-to-length lines

G+K supplies conveyor systems as cross-cutting systems both for the further processing of circuit boards in presses, primarily as semi-finished products for the automotive industry, and for producing circuit board sections of various dimensions as end products of the production line. Special features of G+K systems may include: high throughput speed, high straightness, precise cutting, cutting angle, etc. Some systems are also suitable for small series, meaning that scratch-free rewinding is possible even for sensitive surfaces.

We have manufactured cut-to-length lines from

Coil weight 25 t

Material width up to 2000 mm

Material thickness up to 10 mm

Customizable parameters of our cut-to-length lines

Maximum coil width and thickness

The maximum width and thickness of the coils that can be processed by the system are important technical parameters. These determine the system's capacity and its ability to cut different materials.

Cutting width

The maximum width of the strips that the system can cut is a crucial parameter. This determines the versatility of the system and its ability to handle different applications.

Cutting speed

The speed at which the system can cut the coils affects production performance. It is usually measured in meters per minute (m/min).

Accuracy

Cutting accuracy determines how precisely the system can cut the strips. Higher accuracy is important for applications that require precise dimensions.

Automation

Modern cross-cutting systems may feature automated control systems that manage the cutting process, set the desired dimensions, and optimize the material flow.

Straightening system

Some cross-cutting systems are equipped with a straightening system that aligns the cut material to ensure high quality of the strips.

Variety of materials

The system is capable of cutting a variety of materials, including steel, aluminum, stainless steel, and other metal alloys.

Construction and materials

The design and the materials used affect the durability of the system. Robust constructions and high-quality materials can extend the lifespan.

Ease of maintenance

Maintenance friendliness and access to components are important considerations to ensure smooth operational uptime.

Would you like to learn more about our cross-cutting systems?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- joint conceptual discussion for the new cross-cutting line

- first sketches of the new machine

- Discussions with design and production

- Access to confidential videos

Please feel free to contact me to arrange an appointment regarding cross-cutting lines.