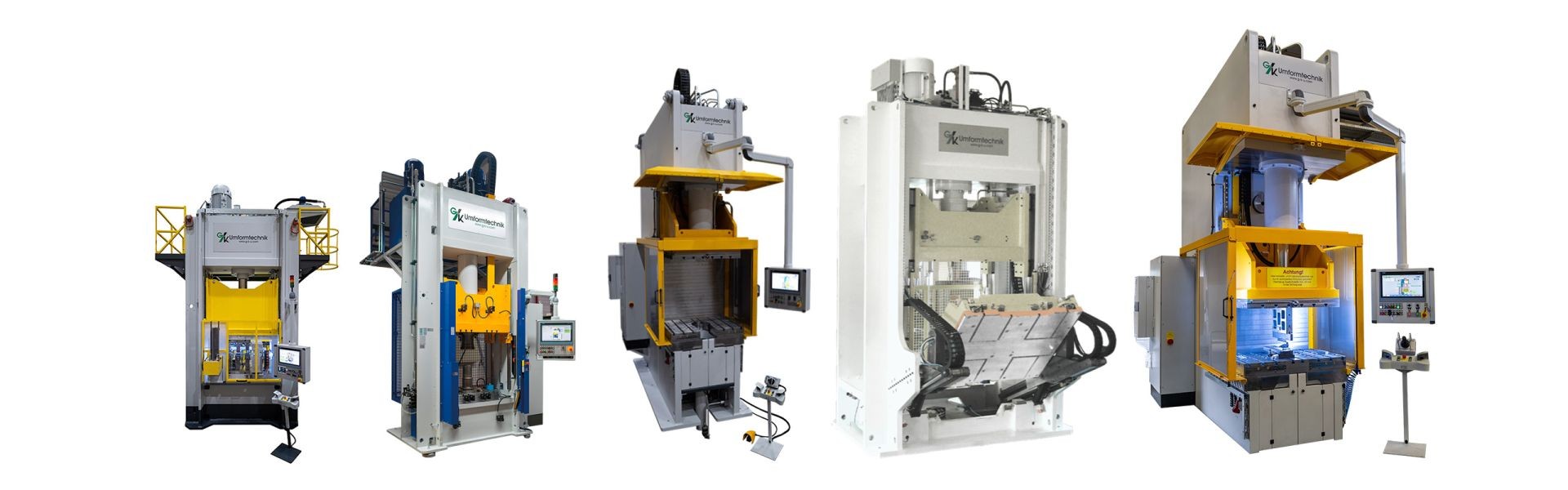

Customizable Bottom Ram Presses from G+K

What are Bottom Ram Presses?

Bottom Ram Presses are a specific type of press used in metal forming and other industrial applications. These presses use a hydraulic mechanism in which pressure is generated by a piston moving from below upwards. The working piston is positioned below the work table, which explains the name "sub-piston press."

Customizable Parameters of Our Bottom Ram Presses

Force and Pressure

The maximum force that the undercarriage press can exert on the material being processed is measured in tons or kilonewtons (kN). The hydraulic pressure required to achieve this force is also an important parameter.

Work Area

The size of the work area or table on which the material is placed varies. The dimensions of the work area affect the maximum size and shape of the material that can be processed.

Stroke Length

The maximum stroke length indicates how far the piston can move from the bottom to the top. This affects the depth of forming or processing that can be achieved in a single operation.

Speed

The speed at which the piston moves influences production performance. It is typically measured in millimeters per minute (mm/min).

Adaptability

Some undercarriage presses offer customization options for various tools and dies. This allows for different forming and processing operations.

Hydraulic System

The type of hydraulic system, including pump performance and pressure regulation, affects the efficiency and accuracy of the press.

Control System

Modern undercarriage presses may come equipped with advanced control systems that enable process control, monitoring, and potentially automation.

Safety Features

Safety features such as emergency stop buttons, protective covers, and light curtains are important for ensuring operator safety.

Construction and Materials

The construction and materials used influence the durability of the press. Robust designs and high-quality materials can increase the lifespan.

Noise Level

The noise level produced by the press during operation can vary depending on the model. Some presses are equipped with noise reduction systems.

Maintenance Friendliness

Access to components and ease of maintenance are important considerations for ensuring smooth operation.

Would you like to learn more about our Bottom Ram Presses?

We would be happy to discuss your specific case in a non-binding conversation. You can expect the following:

- Joint concept discussion for the new Bottom Ram Press

- Initial sketches of the new machine

- Conversations with design and production

- Access to confidential videos

Please feel free to contact me to schedule an appointment regarding the Bottom Ram Press.