Conversion of an old press

Retrofit

The conversion of an old press is always an exciting challenge for us because it often requires us to apply all of our press expertise. Every project like this presents a unique opportunity to revitalize older machines and adapt them to meet modern production standards, all while maintaining the integrity and functionality of the original equipment. This process often involves detailed planning, the integration of advanced technologies, and careful engineering to ensure the press can perform optimally for the customer's specific needs.

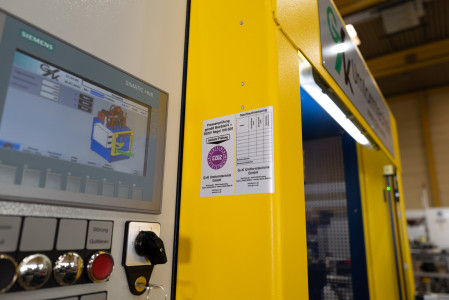

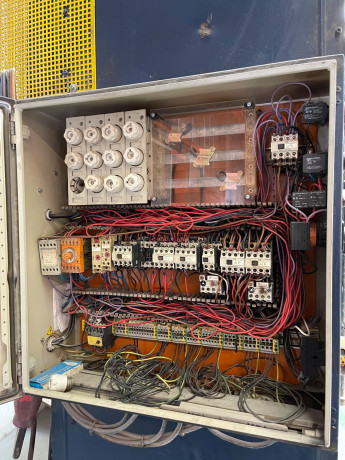

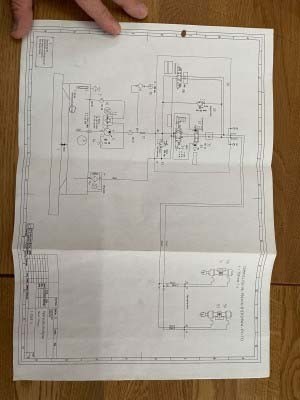

Here, you can see an example of a press conversion project we undertook. The goal was to update and modernize an aging press to enhance its efficiency, improve its safety features, and ensure that it meets the latest industry standards. This conversion not only required replacing outdated components but also involved upgrading the press's control systems, hydraulic systems, and automation features to allow for faster cycle times and higher precision. Additionally, we implemented state-of-the-art monitoring and diagnostic tools to provide real-time data, enabling more effective maintenance and improving overall machine uptime.

Throughout this project, we drew on our deep understanding of press technology and our extensive experience with both legacy systems and cutting-edge innovations. The challenge was to ensure that the new components integrated seamlessly with the existing structure, maintaining the press's stability and reliability while enhancing its capabilities. The result was a highly functional, modernized press that continues to serve our client for years to come, demonstrating how innovation can breathe new life into older machines and help companies stay competitive in an increasingly fast-paced manufacturing environment.

This example of press conversion highlights the importance of both technical knowledge and creativity when working with older machinery. It's a testament to the fact that with the right approach, even older presses can be transformed into highly efficient, state-of-the-art systems that meet the demands of today's manufacturing world.