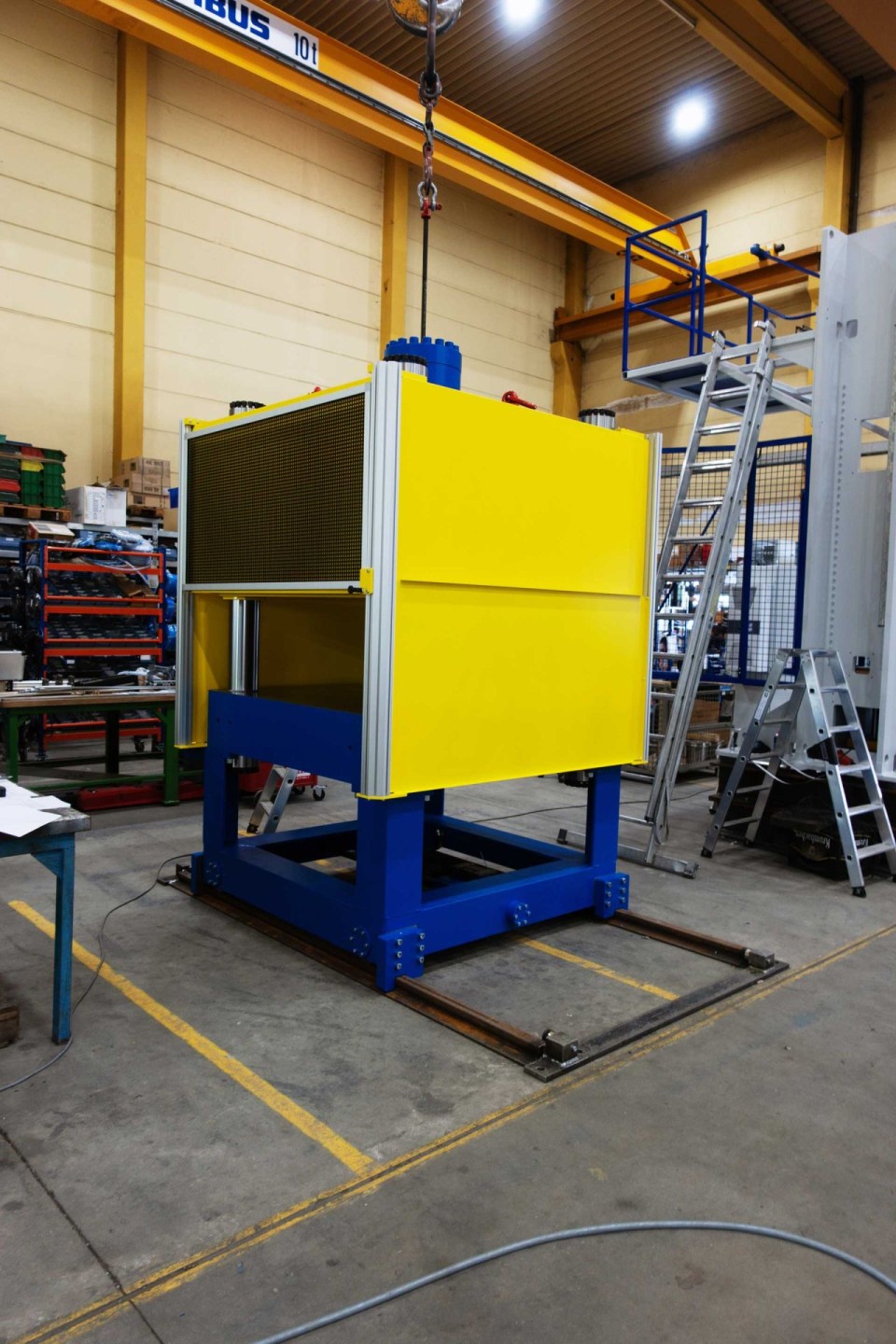

4-column press as a special machine

For one client, we produced a 4-column press as a special machine.

A 4-column press as a special machine is a specialized machine tool designed for specific, individual requirements in manufacturing technology. It is based on the classic design of a four-column press but customized to meet particular applications that go beyond standard functions. These machines are primarily used in industries such as automotive, aerospace, medical technology, and metalworking, where high precision and exceptional load capacities are required.

How a 4-Column Press Works

The 4-column press consists of a sturdy frame with four vertically aligned columns that support the movable and fixed parts of the press. The upper press ram (or upper tool) is driven downward by hydraulic or mechanical systems to deform the material between the upper and lower dies. What makes a special machine unique is the customized configuration designed to meet specific requirements.

-

Customized Design: Special machines provide tailored solutions based on the specific production needs of the customer. This may include the integration of specialized tools, measurement systems, or automated handling systems.

-

Versatility: Due to its customization options, a 4-column press as a special machine can cover a wide range of applications, including forming, stamping, and precise testing processes.

-

Hydraulic Control: Special machines are often equipped with advanced hydraulic control systems that allow fine regulation of the pressing force, ensuring high precision throughout the process. This ensures that even complex components are produced with great accuracy.

Benefits of the 4-Column Press as a Special Machine

A 4-column press as a special machine can be tailored to meet specific precision and tolerance requirements. This is especially important in industries where the highest accuracy is essential.

Special machines can be adapted to various materials and shapes, allowing for a broad range of applications.

By integrating automation into the special machine, production capacity and efficiency are improved. Robotic handling systems or automatic loading systems contribute to reduced production times.

The 4-column construction provides exceptional stability and durability, leading to a longer machine lifespan, even under intensive production conditions.

Applications of the 4-Column Press as a Special Machine

-

Automotive Industry: Used to manufacture precise components for vehicle parts, such as body panels, brake components, or transmission parts.

-

Aerospace: For the production of highly precise parts used in extreme conditions, the 4-column press as a special machine provides the necessary accuracy and stability.

-

Medical Technology: In medical technology, special machines can be used to produce medical devices and components that must meet strict quality and safety standards.

-

Metalworking: In metalworking, 4-column presses as special machines are commonly used for stamping and forming metal parts.

A 4-column press as a special machine is an extremely flexible and powerful solution for producing high-precision, customized components. It offers high adaptability and can be equipped with specialized features to meet the specific needs of industrial companies. Thanks to its stability, versatility, and efficiency, it is a valuable machine in many demanding manufacturing processes.