Wheel Press and Wheel Drill

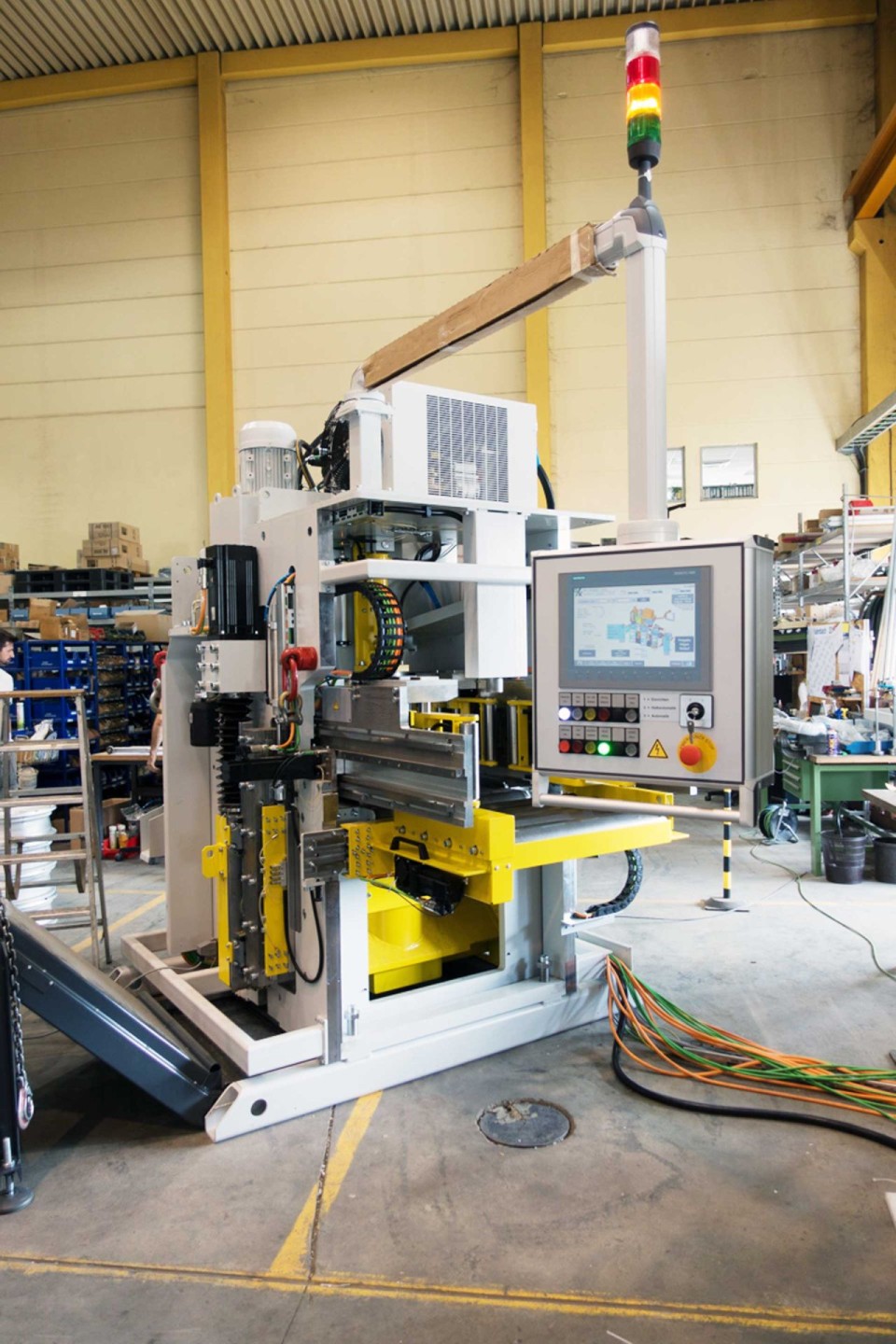

Here, for example, are the final stages in the construction of a continuous drilling rig, a crucial component in many industrial processes. This rig was meticulously designed and built to meet the specific requirements of the customer, ensuring maximum efficiency and precision in the drilling operations. The customer received not only a wheel press but also a wheel drill, both of which are essential tools for the production of high-quality aluminum rims.

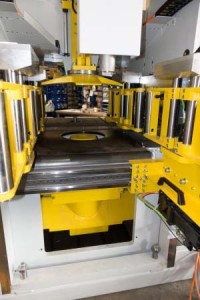

The wheel press plays a vital role in the shaping and assembly of rims. It ensures that the aluminum rims are perfectly formed, meeting strict dimensional and structural requirements. This machine is equipped with advanced hydraulic technology that guarantees precise and efficient pressing, minimizing material waste and improving overall productivity.

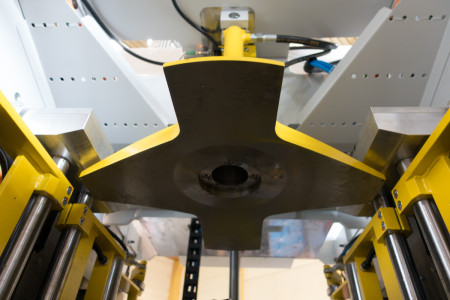

In addition to the wheel press, the wheel drill is another key piece of equipment that was provided to the customer. The wheel drill is designed to create holes in the rims with high accuracy, allowing for the precise fitting of parts such as valve holes or balancing holes. It operates at high speeds without compromising the quality of the final product, ensuring that each rim is drilled according to the exact specifications needed for further manufacturing processes.

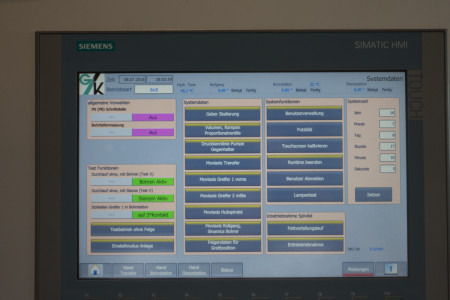

The construction of this continuous drilling rig was an intricate process that required expertise in both mechanical design and automation. From the initial stages of planning and prototyping to the final assembly and testing, every step was carried out with meticulous attention to detail. The final product was a fully integrated system capable of providing reliable and consistent performance in high-volume production environments.

By providing the customer with both the wheel press and the wheel drill, we ensured that they had a complete solution for the efficient production of aluminum rims. This combination of equipment allows for a seamless manufacturing process, where the shaping and drilling of the rims are carried out in an integrated, automated manner. This not only increases the overall production speed but also enhances the consistency and quality of the finished products.

Overall, the successful completion of this continuous drilling rig highlights our ability to design and deliver customized manufacturing solutions that meet the unique needs of our customers. The customer is now equipped with state-of-the-art machinery that will help them meet the growing demand for high-quality aluminum rims, while also improving their production capabilities and operational efficiency.