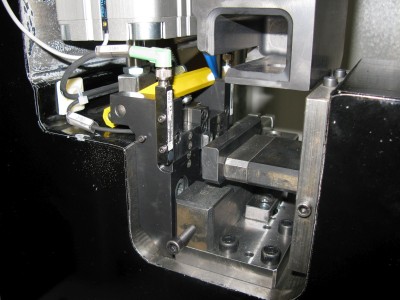

Part leveller for small assembly groups

For the further processing of small assembly units made from various sheet metal components, it is necessary to calibrate certain connection dimensions to ensure they can be used in the subsequent automated assembly production. This calibration step is critical because it ensures that all components fit together precisely and meet the strict tolerance requirements needed for efficient automated assembly.

The calibration process involves measuring and adjusting the dimensions of the connection points between the sheet metal components, such as flanges, edges, and joints. This guarantees that the components align correctly and can be assembled seamlessly by automated systems without the need for manual intervention. Accurate calibration also helps prevent issues during the later stages of production, such as improper fit or malfunctioning of the final assembly.

In addition to ensuring proper fitment, the calibration process also improves the overall quality and functionality of the final product. By ensuring that all connection dimensions are consistent and within the required specifications, manufacturers can achieve higher levels of precision in the finished assembly, which is especially important in industries such as automotive, aerospace, and electronics, where precision is essential.

This step also contributes to optimizing the overall production process. By calibrating the parts beforehand, the automated assembly systems can work more efficiently and with fewer disruptions. This reduces the likelihood of errors, minimizes downtime, and enhances the overall throughput of the production line. Additionally, it helps reduce waste and rework, as calibrated parts are less likely to require adjustments or reprocessing later in the production process.

Ultimately, the calibration of connection dimensions plays a crucial role in streamlining the manufacturing process, improving product quality, and ensuring that small assembly units can be seamlessly integrated into automated systems for efficient and reliable mass production.