Strip cut-to-length line for copper

Cross-Cutting Line for Copper

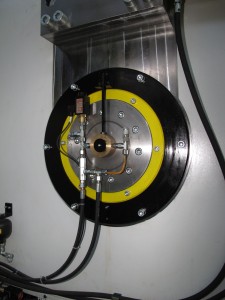

The cross-cutting line was specifically developed for processing highly sensitive copper materials used in the design and architecture industry. Copper, known for its aesthetic and functional qualities, is frequently employed in high-end projects where material quality and processing are of the utmost importance. The unique challenge with copper lies in its softness and vulnerability to scratches and dents, which means that special care must be taken during handling. Therefore, particular attention was given to ensuring that the copper could be unwound and rewound without any scratches or surface imperfections. The precise control and technology of the line ensure that the material remains optimally protected during every stage of processing.

Copper is a material that can lose its aesthetic value even with the smallest damage, which is unacceptable in the design and architecture industries. To address this challenge, the cross-cutting line is equipped with advanced technology that allows for gentle handling of the material during the entire unwinding and rewinding process. The precise control over speed, tension, and positioning ensures that the copper remains protected throughout the process. This technology guarantees that the material not only retains its original form but also preserves its aesthetic qualities, such as shine and surface texture.

Another key aspect in the development of the cross-cutting line was the ability to process small production batches. In many design and architecture projects, only small quantities of copper are required, which increases the demands on the production equipment. This small batch size requires high adaptability, and the line must be able to quickly respond to changing production requirements while ensuring precise material processing. The cross-cutting line excels in meeting these demands, enabling efficient processing of various formats and material quantities without compromising on quality.

Particular attention was also given to the rewinding process to ensure that the copper is rolled up without damage after processing. The rewinding mechanism of the cross-cutting line was specifically tailored to copper's properties, ensuring that the material is unwound under low, consistent tension and rolled evenly. This prevents damage to the copper during the rewinding process, such as from excessive roll speeds or uneven tension, ensuring the material remains in perfect condition for further processing or shipment.

The cross-cutting line is not only an effective solution for processing copper in small batches but also contributes to improving overall efficiency. It minimizes waste and reduces the need for reworking by integrating the entire process, from unwinding to rewinding, into a single streamlined system. This efficiency is particularly important for companies in the design and architecture industries, where high material costs and strict deadlines demand maximum precision and cost-effectiveness.

Additionally, the cross-cutting line ensures that the copper material retains its aesthetic qualities throughout the process. This is crucial for projects where the material plays an important role not only in functionality but also in its visual appeal, such as in architectural elements, decorations, or artwork. The line guarantees that the high-quality surface of the copper remains undisturbed after processing, with no unsightly scratches or dents that could affect the final product.

The innovative technology employed in the cross-cutting line also ensures high operational stability and low maintenance costs. This allows businesses to reduce production times without compromising quality. The machine is designed to function reliably even under changing production conditions, providing consistently high processing quality.

In summary, the cross-cutting line for copper represents an ideal solution for handling sensitive materials in the design and architecture industry. It enables gentle and precise processing that preserves the aesthetic quality of the copper, while also ensuring high flexibility in small batch production. The combination of advanced technology, precise control, and adaptable handling makes the cross-cutting line an indispensable tool for companies that need to manufacture high-quality copper products with precision and efficiency.